THE BP- CONTROL FEATURES

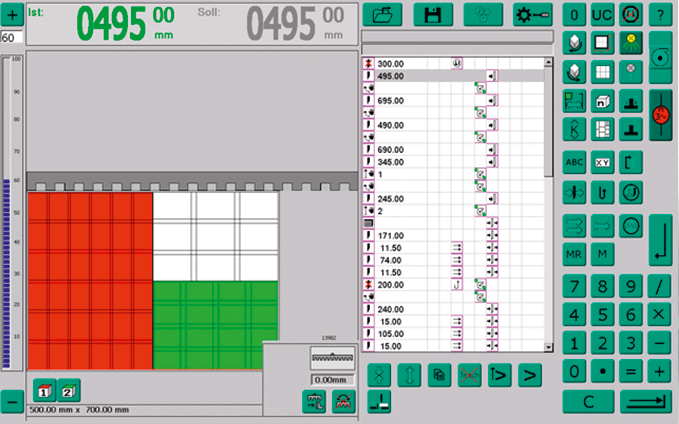

The user friendly 18.5” high resolution color touch screen has a graphic operating surface that shows each step of the cutting process for easy control during programming and operation. Work with process visualization and Auto-program mode to create multiple-up jobs in just a few seconds or use the ‘Simple-mode’ for a few cuts between your bigger cutting jobs.

STANDARD FEATURES

Graphic operating surface

CIP 3 /4 enabled, CIP converter built-in

Operating mode adaptable to operator's preference

Memory of up to 30,000 programs

Auto- Program mode for creation of cutting jobs in seconds

Multi- language support

Measuring system for both, inch and metric

Clamp pressure adjustment by finger touch directly on screen

Automatic adaption of clamp pressure to actual sheet width at each cut

LED table light and cut line indicator

Electronic hand dial at the front table for digital fine adjustment of the backgauge by 1/1000”

Programmable slow motion feature for backgauge

Programmable automatic knife

Programmable automatic clamping without cutting

Calculator

Cut counter

Correction of sheet size deviations

Knife change reminder

Knife change guided on screen

Help menu, including operator manual on screen

Electronic knife thickness correction

Variable clamping time extension for soft or sensitive material

USB port for program backups, program transfers, and software upgrades

Ethernet connection for networking

S2C - STRAIGHT TO CUT

JDF files from pre-press or the digital workflow are sent via network directly to a hotfolder. When the job arrives at the cutting system, the operator scans the barcode that contains the name of the job.

The optional S2C is the most versatile solution to extend your digital workflow to the cutting department.

The size of the job doesn’t matter anymore. No time Is wasted at the cutter for programming. This is profitable On Demand Cutting even for a job size of one printed sheet. The solution can also be integrated in the D2F (Direct-To-Finish) workflow from HP.

The Cuttronic software converts the jdf- data immediately into a cutting program. A second later the print image is displayed on screen and the operator is able to make the first cut and run the job.