SEMI-AUTOMATIC SOLUTIONS

CUTTING SYSTEM WITH FULLY-AUTOMATIC PAPER JOGGING

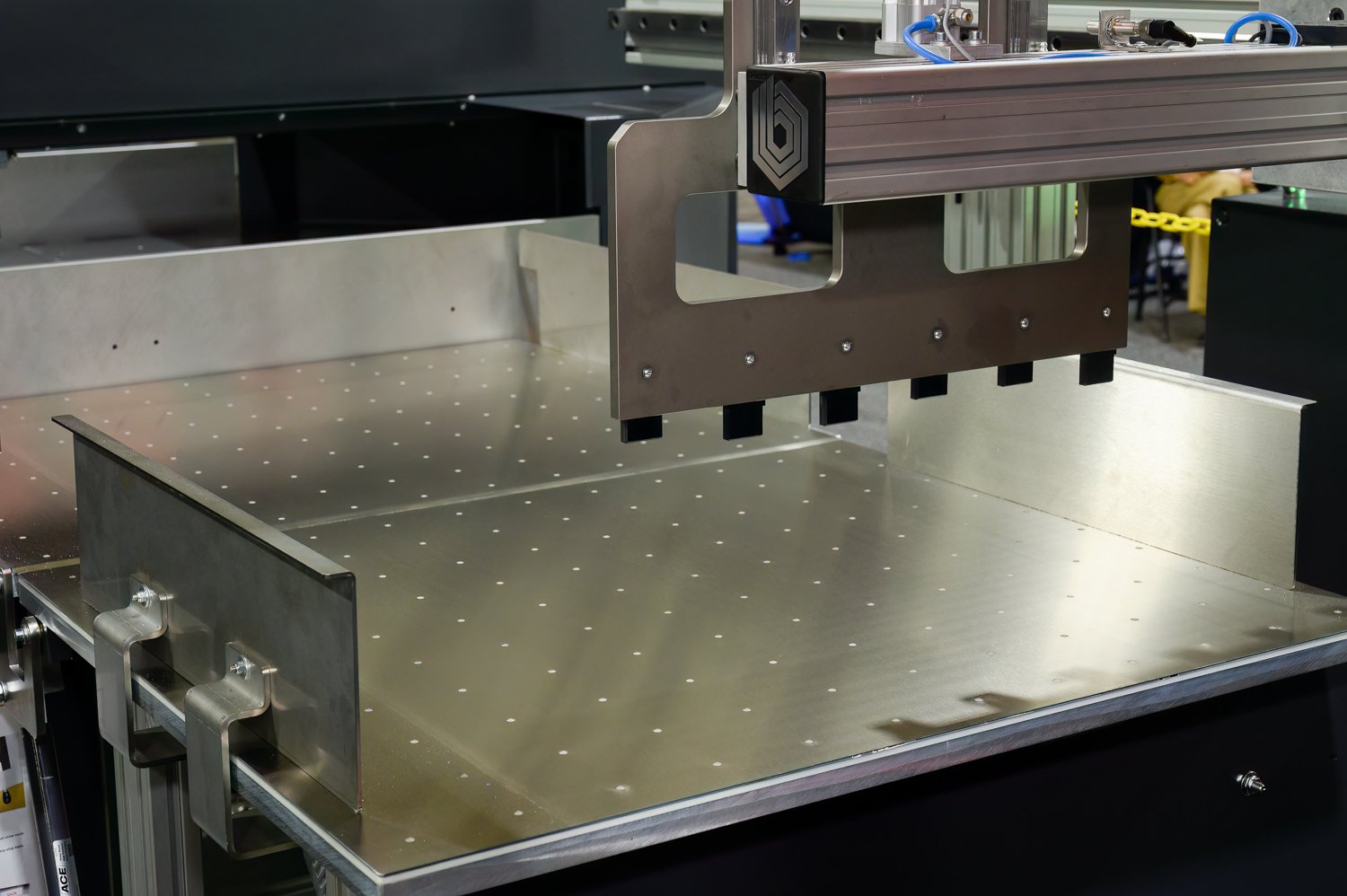

This is a real powerhouse. A BAUMANN-PERFECTA high-speed guillotine BP 132 combined with a fully automatic jogging system BASA Evolution and rear table feeding with Pusher system BTE. An automatic waste removal system AWR adds additional efficiency to the workflow and re-stacking of finished products with Automatic Unloader BA 3 lets the operator focus on the cutting job and makes this cutting system the most ergonomic and fastest semi-automatic solution in the market.

This system can also be configured with rear table loading or automatic 4-side cutting.

VIDEO: Fully-automatic jogging, cutting, and automatic re-stacking taking place simultaneously.

Jogging without jogger operator. The paper lifts are automatically delivered to the buffer space or directly into the cutter, either to the rear table or onto the side table at the front.

CUTTING SYSTEM AUTO4CUT

The material is jogged by the operator while the the cutting system is doing a fully automatic 4-side cutting on the previous lift of paper. The automatic positioning system BDG 3e turns the lift after each cut. The AUTO4CUT includes automatic loading from the front and re-stacking of the finished products precisely on a pallet by the automatic unloader BA 3.

VIDEO: AUTO4CUT system in action

The unique BAUMANN-PERFECTA system AUTO4CUT performs 4-side cutting with side alignment and alignment from the front. This guarantees highest cutting accuracy after the automatic loading process and even during the automatic 4-side cutting. After the 4-side trim the front loading system will move out of the way automatically so the operator can execute any split cuts and finish the cutting job.

If necessary, the front loading unit can be moved out of the way within a few seconds by releasing a quick lock and the cutting system can be used like a standard system.