THE PERFECTA FEATURES

THAT MAKE THE DIFFERENCE

CUTTING PRECISION AND HIGH-SPEED PERFORMANCE

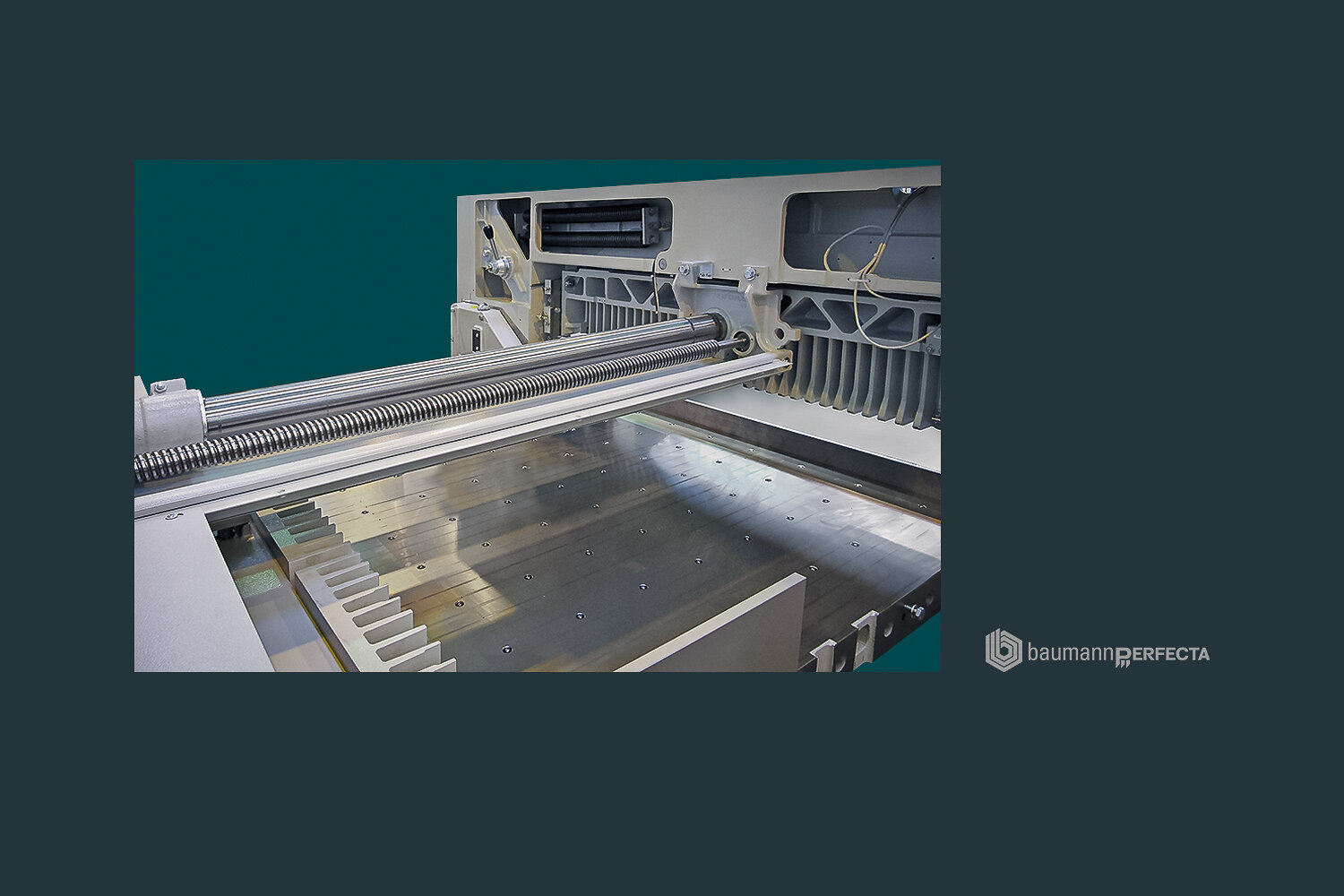

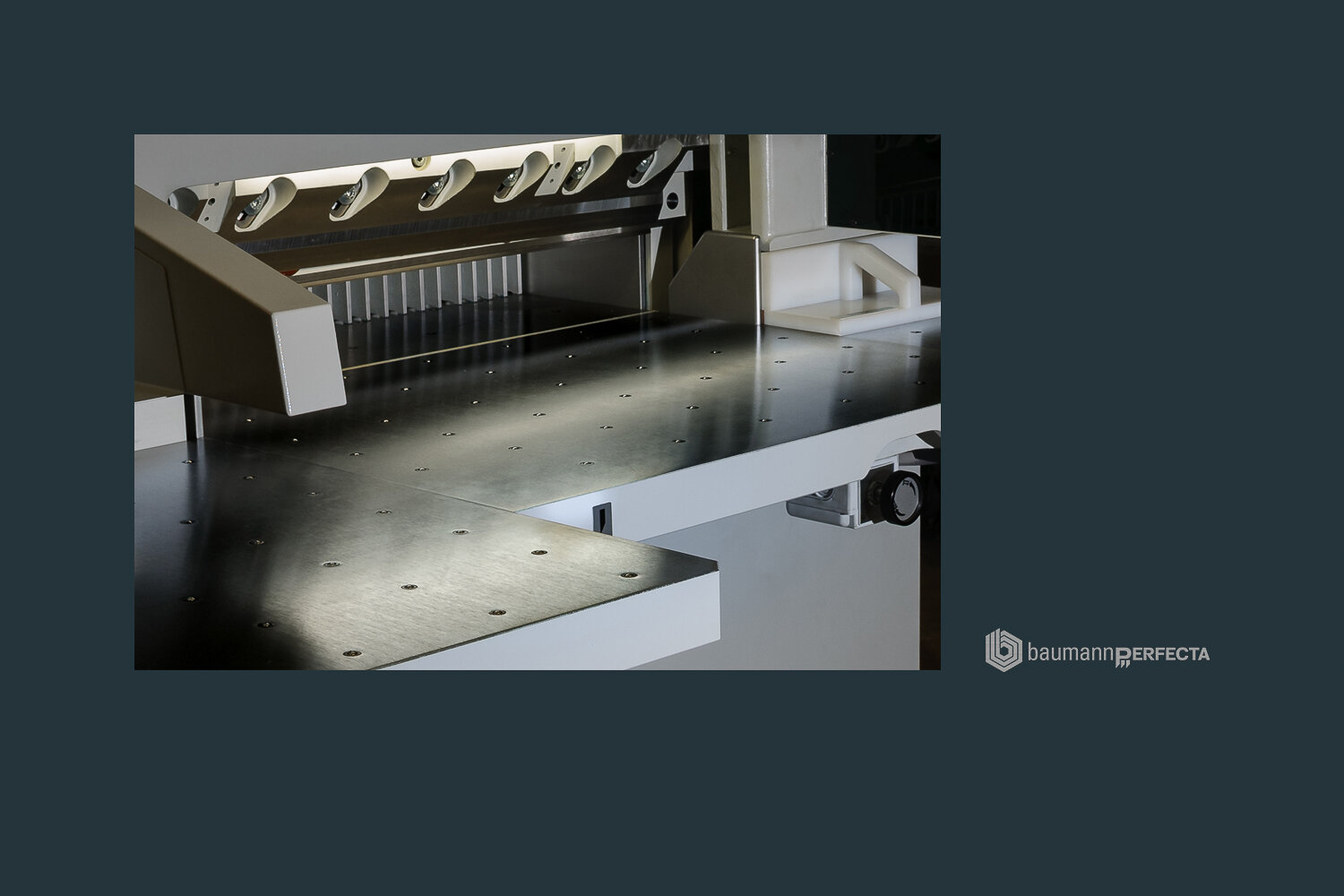

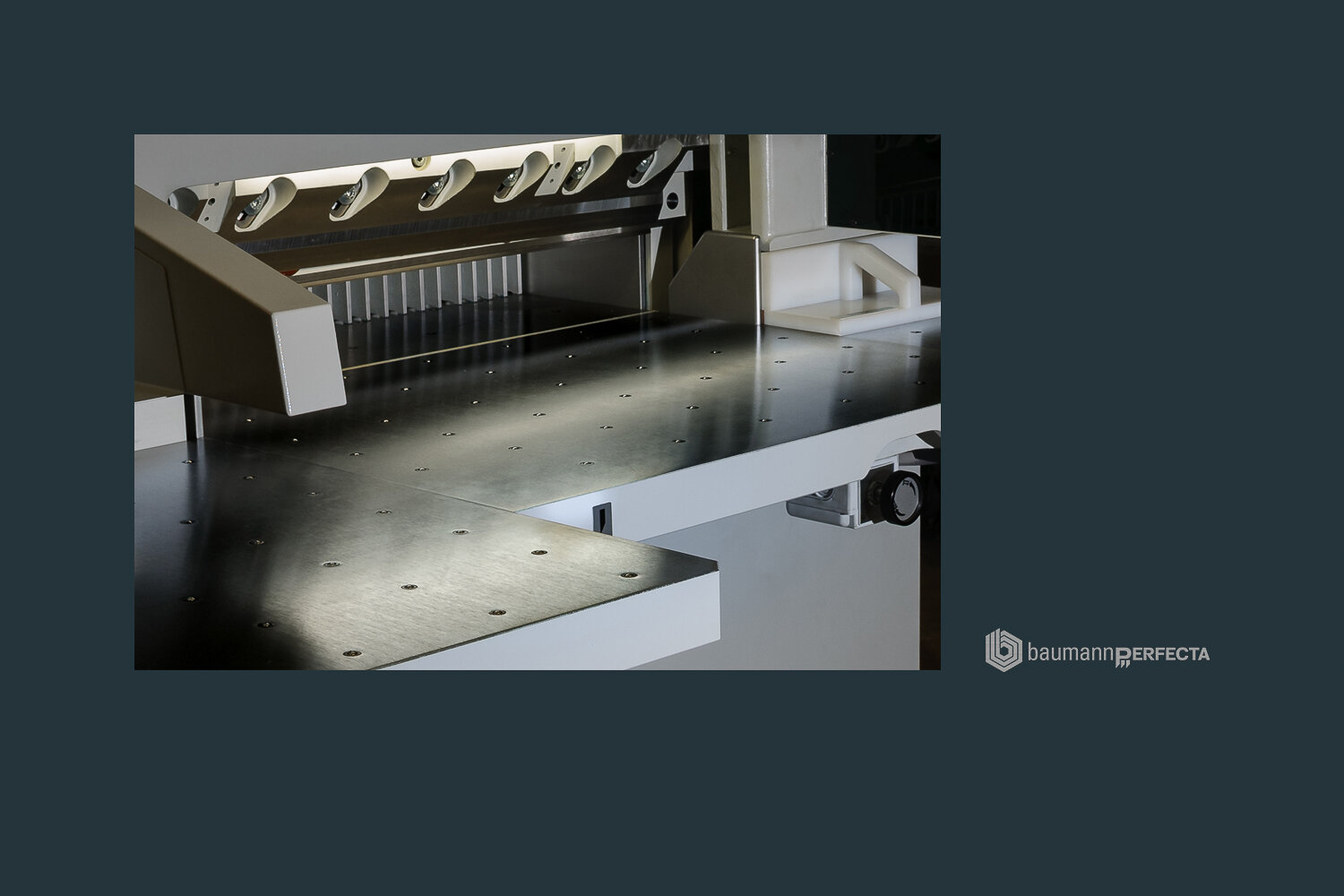

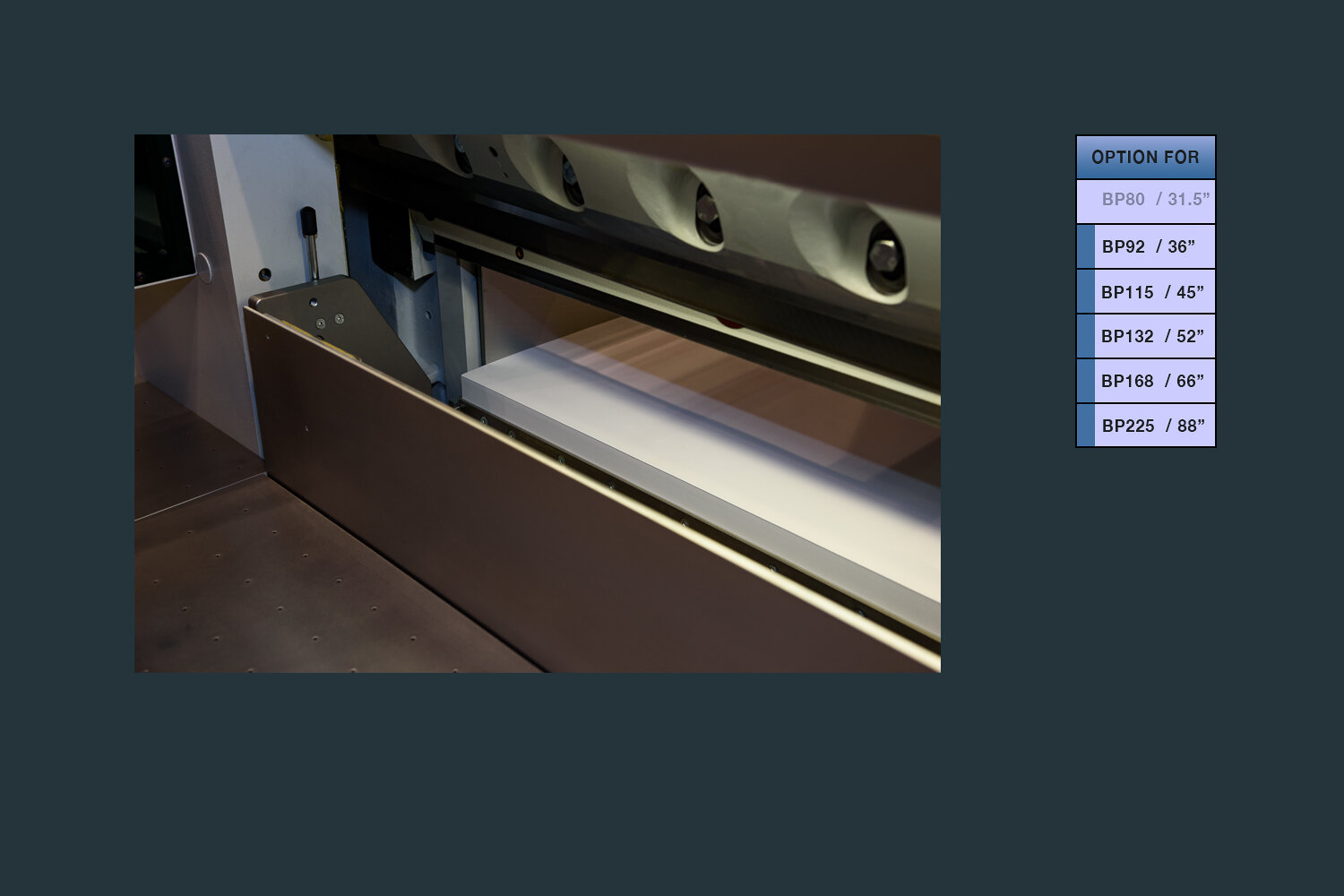

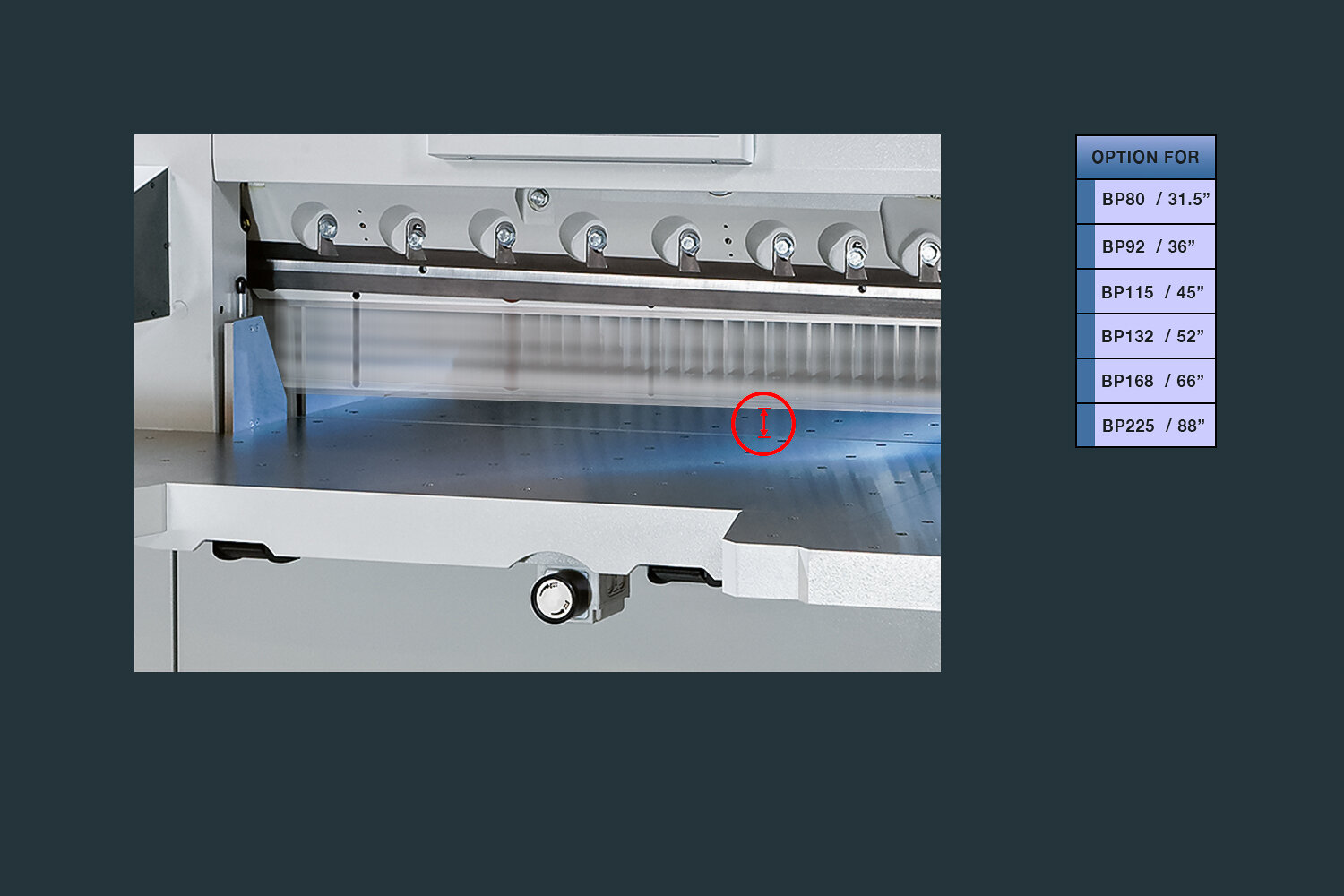

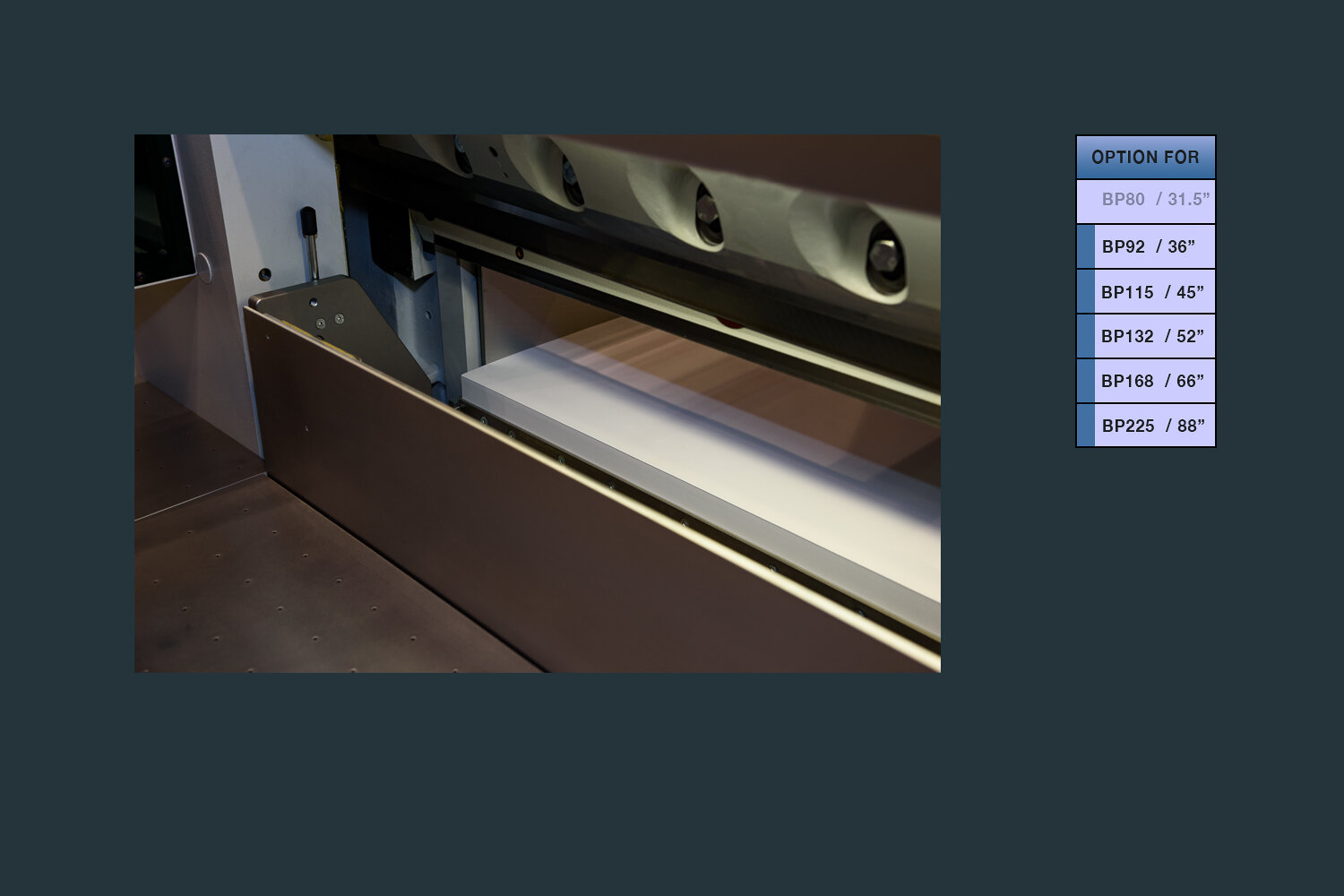

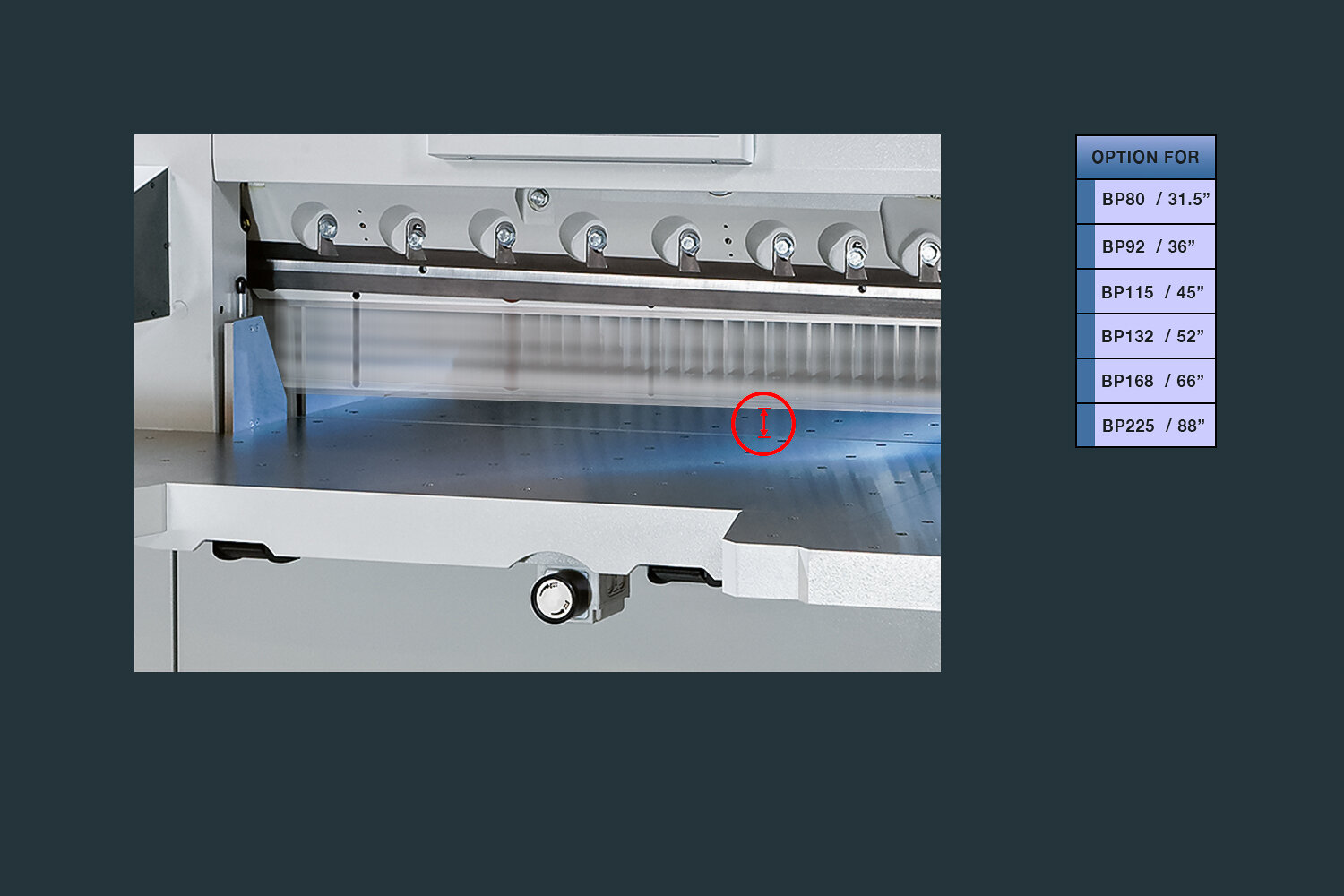

The sturdy slot-less table benefits cutting accuracy. No dealing with any cover belt and no damage of the bottom sheets.

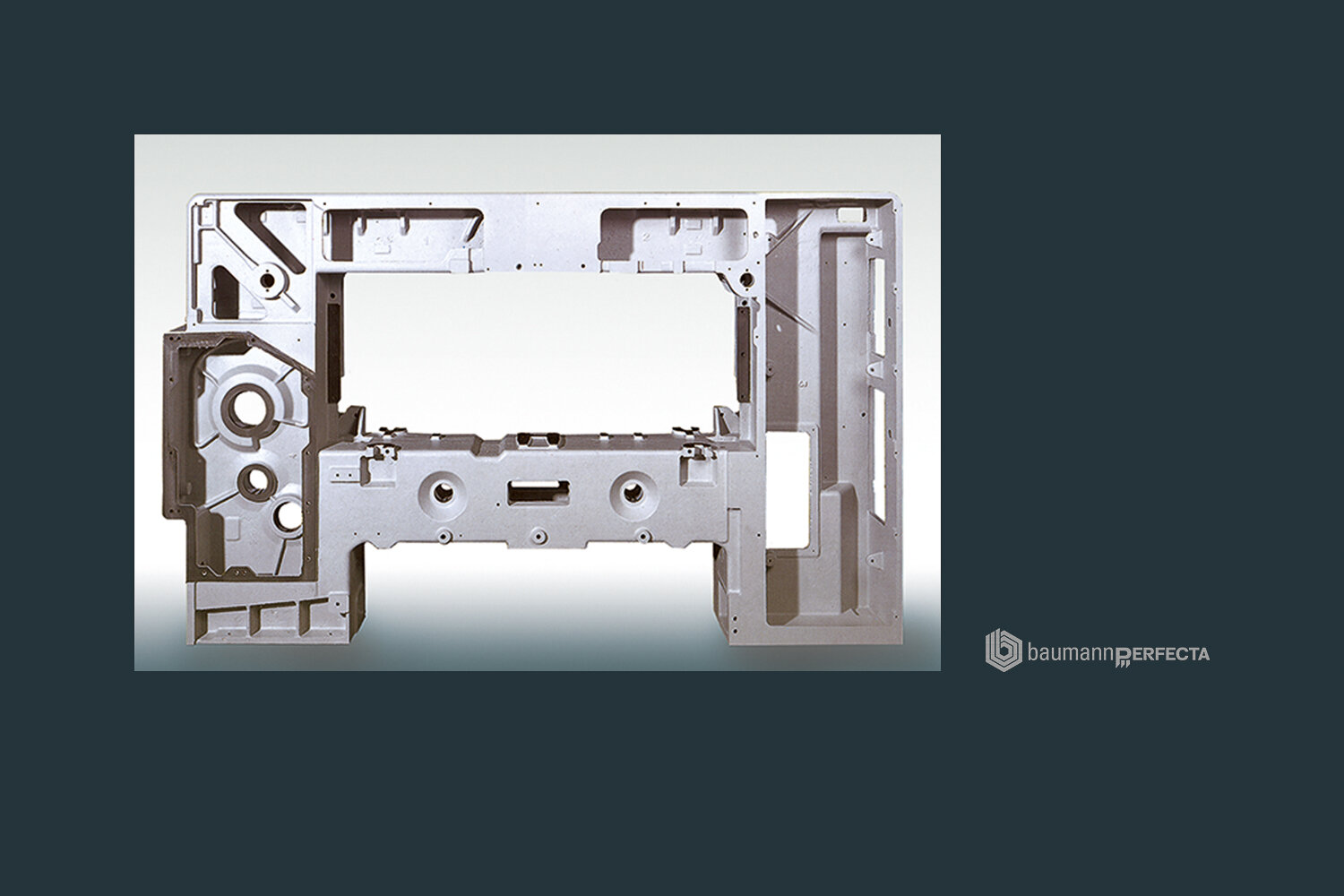

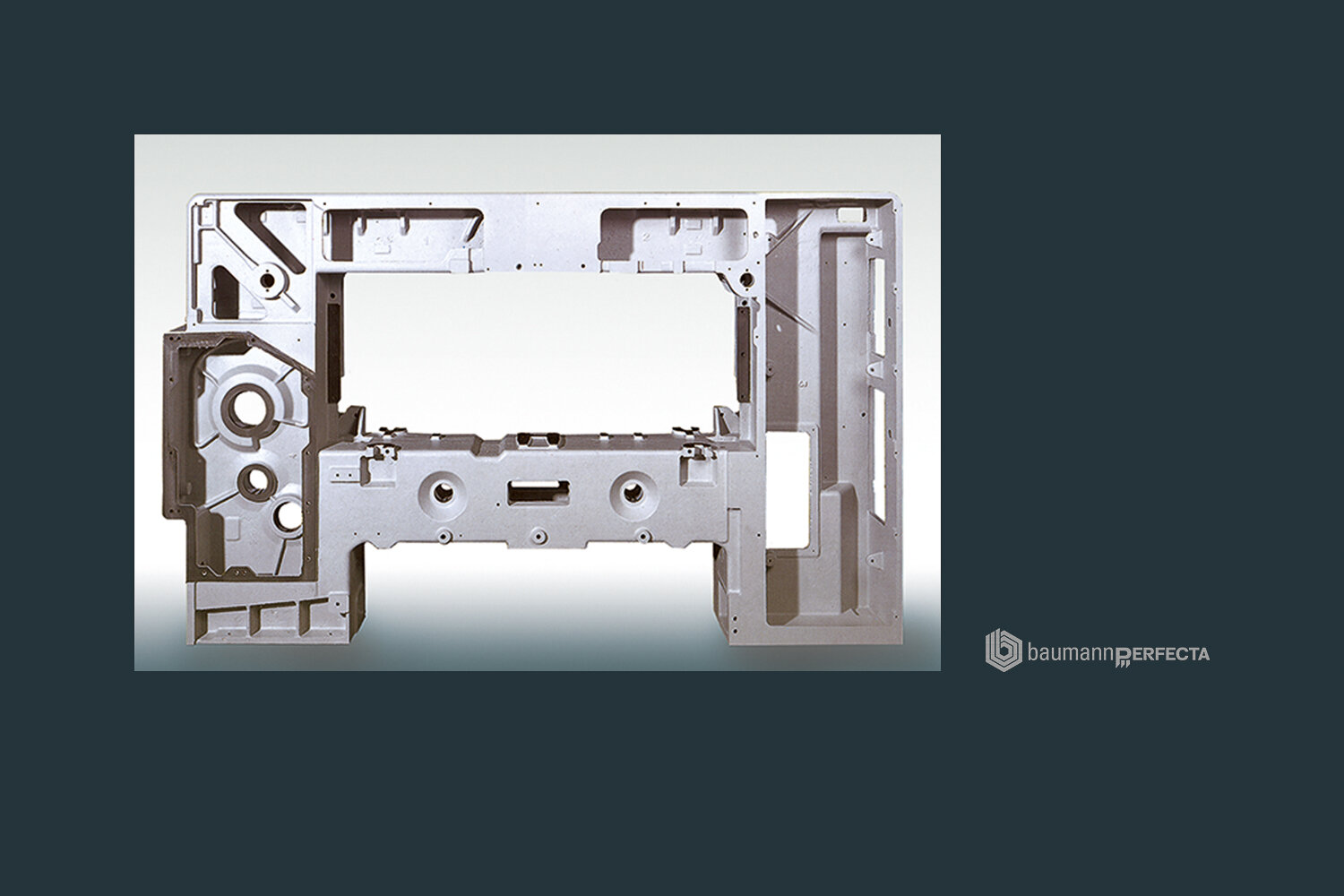

The extreme stability of the cast iron machine frames is the basis for the high cutting accuracy of any PERFECTA cutter.

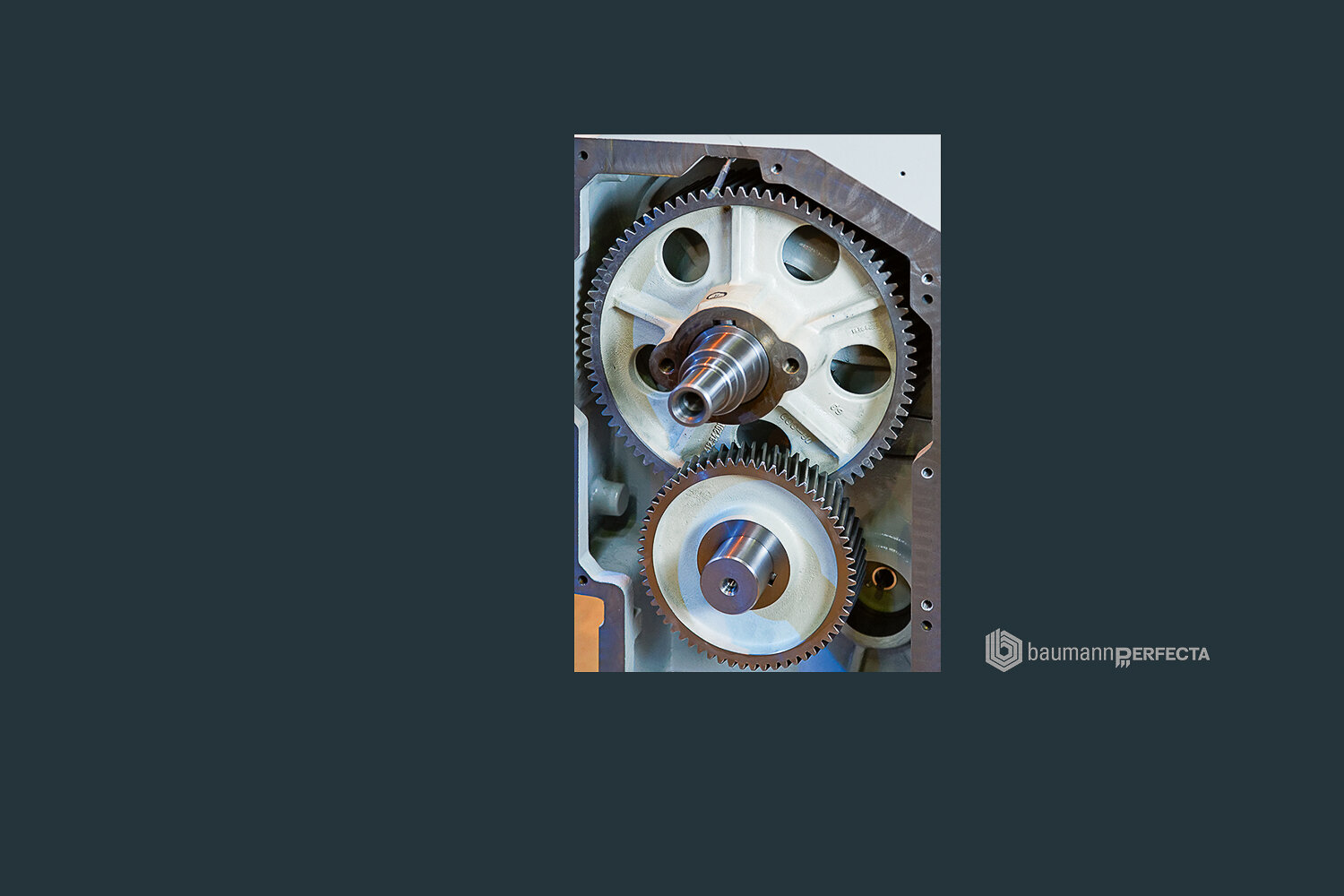

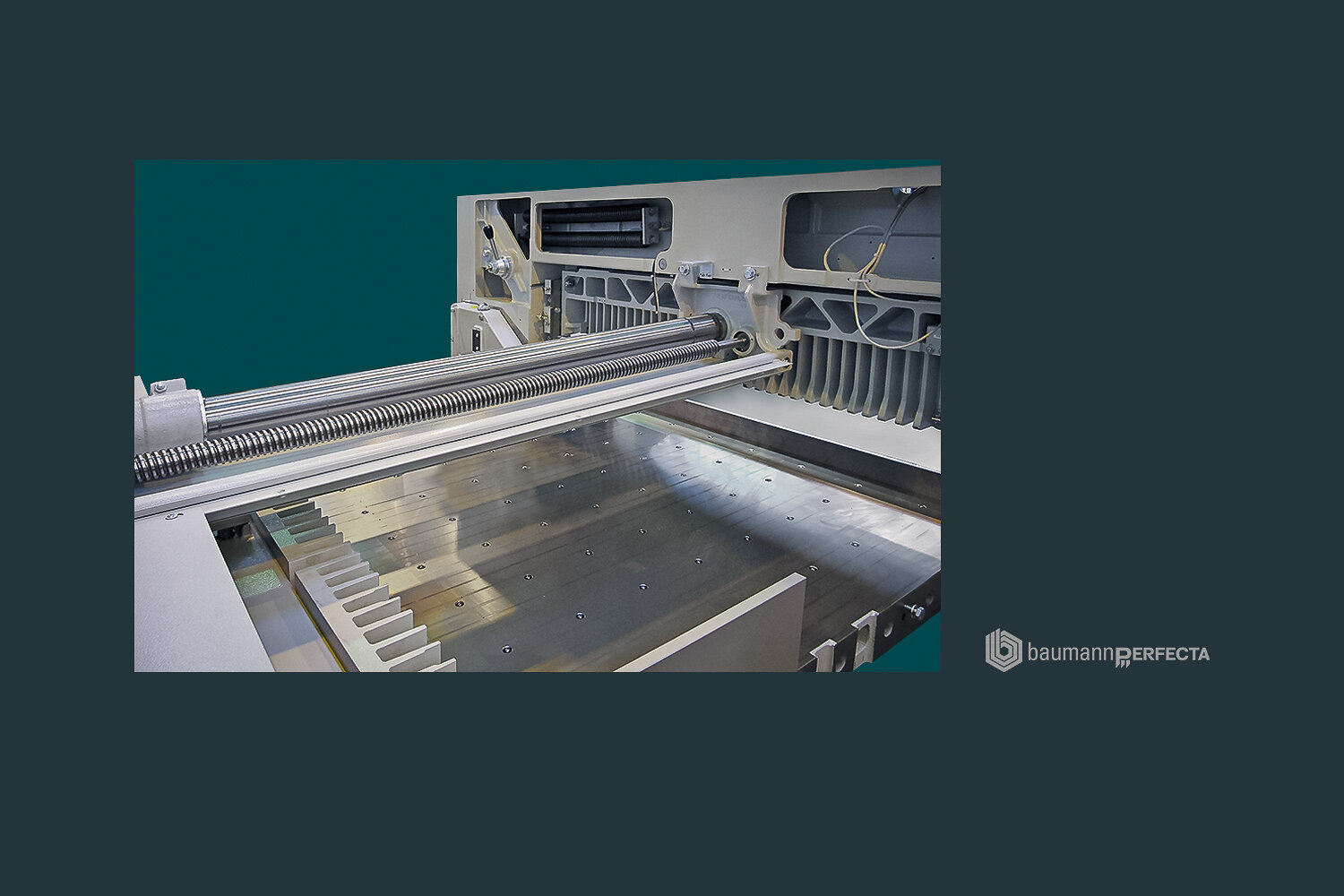

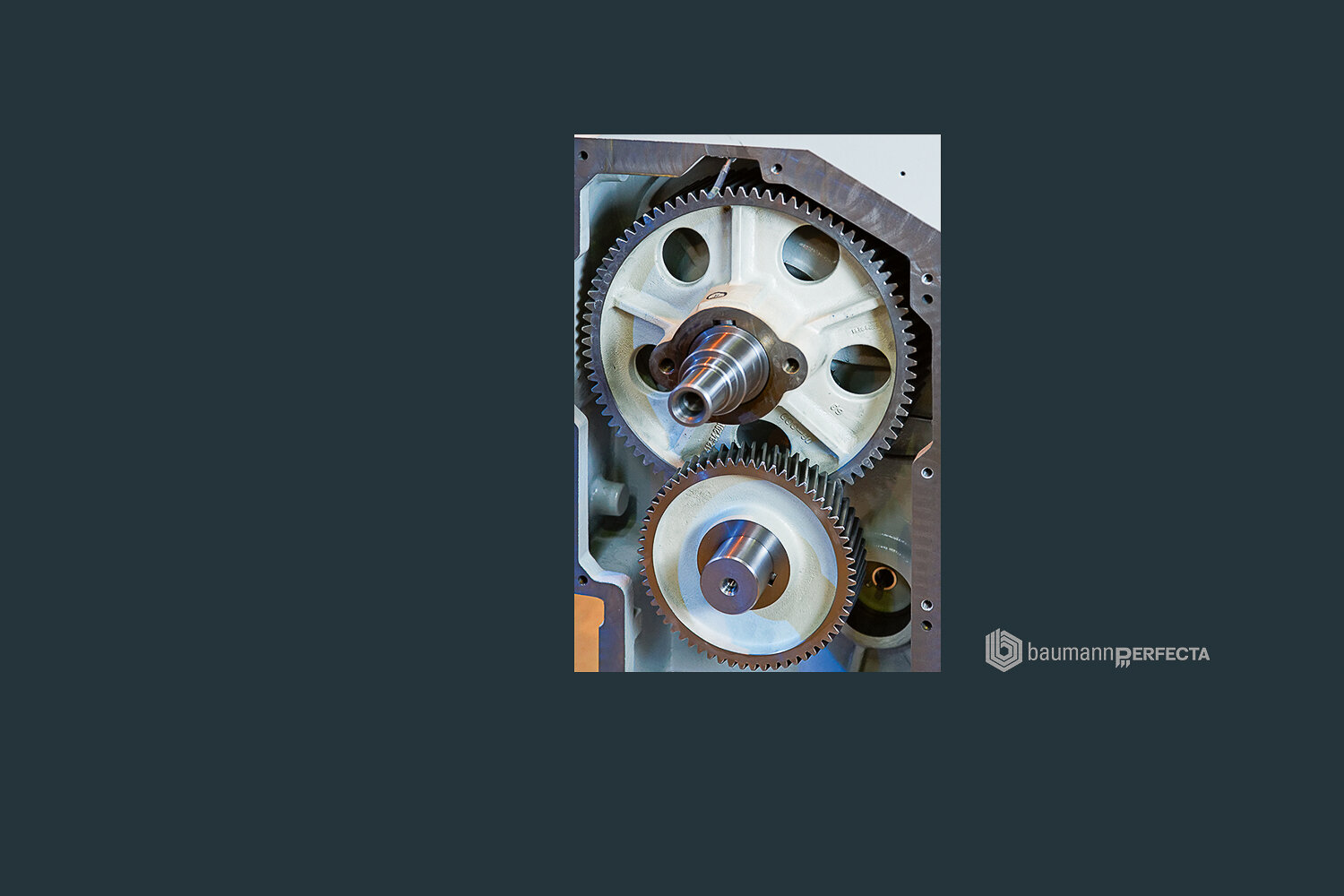

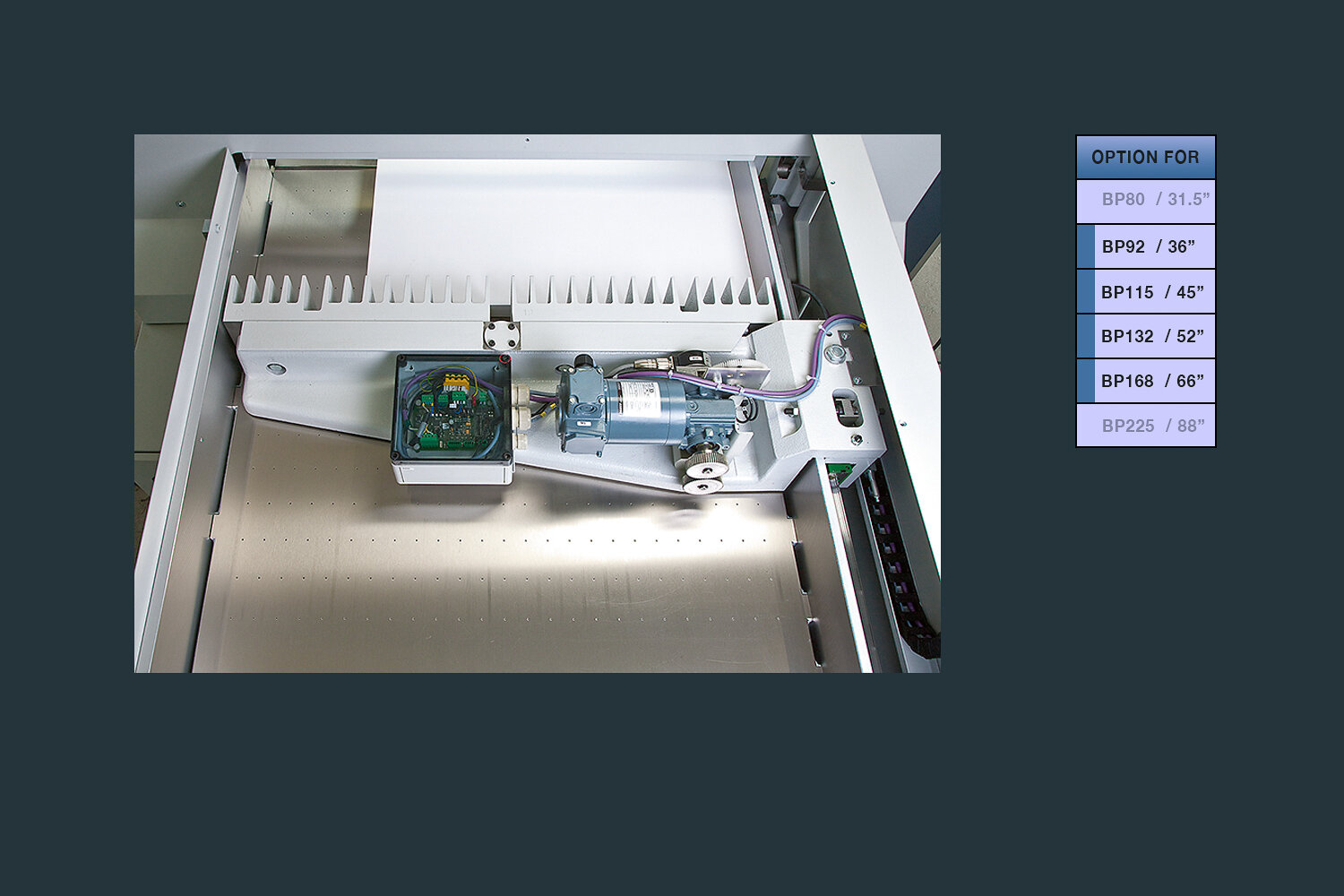

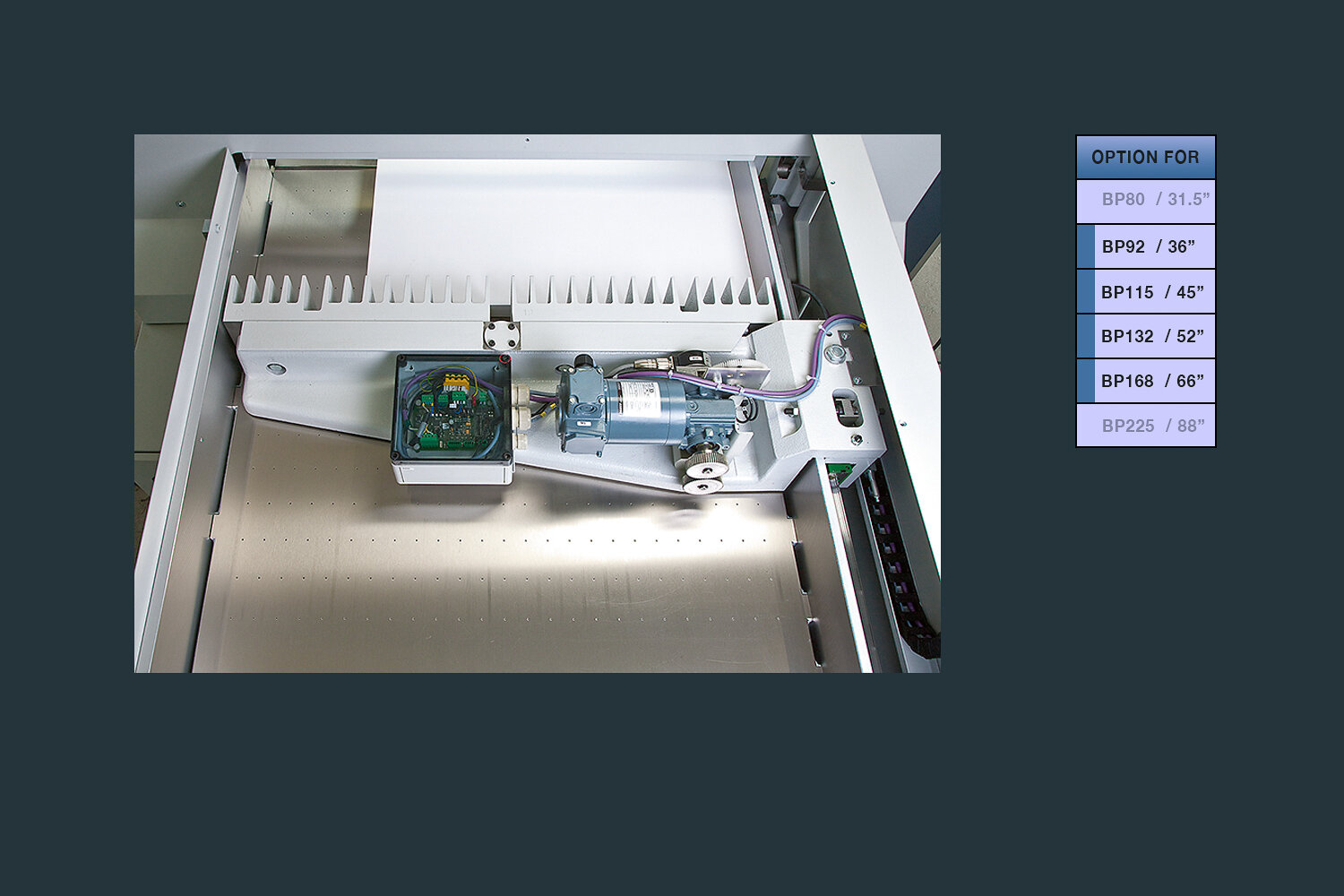

For all PERFECTA 115 to 225 gear box systems. Backed by an unheard of 10-year warranty, it is the strongest in the world.

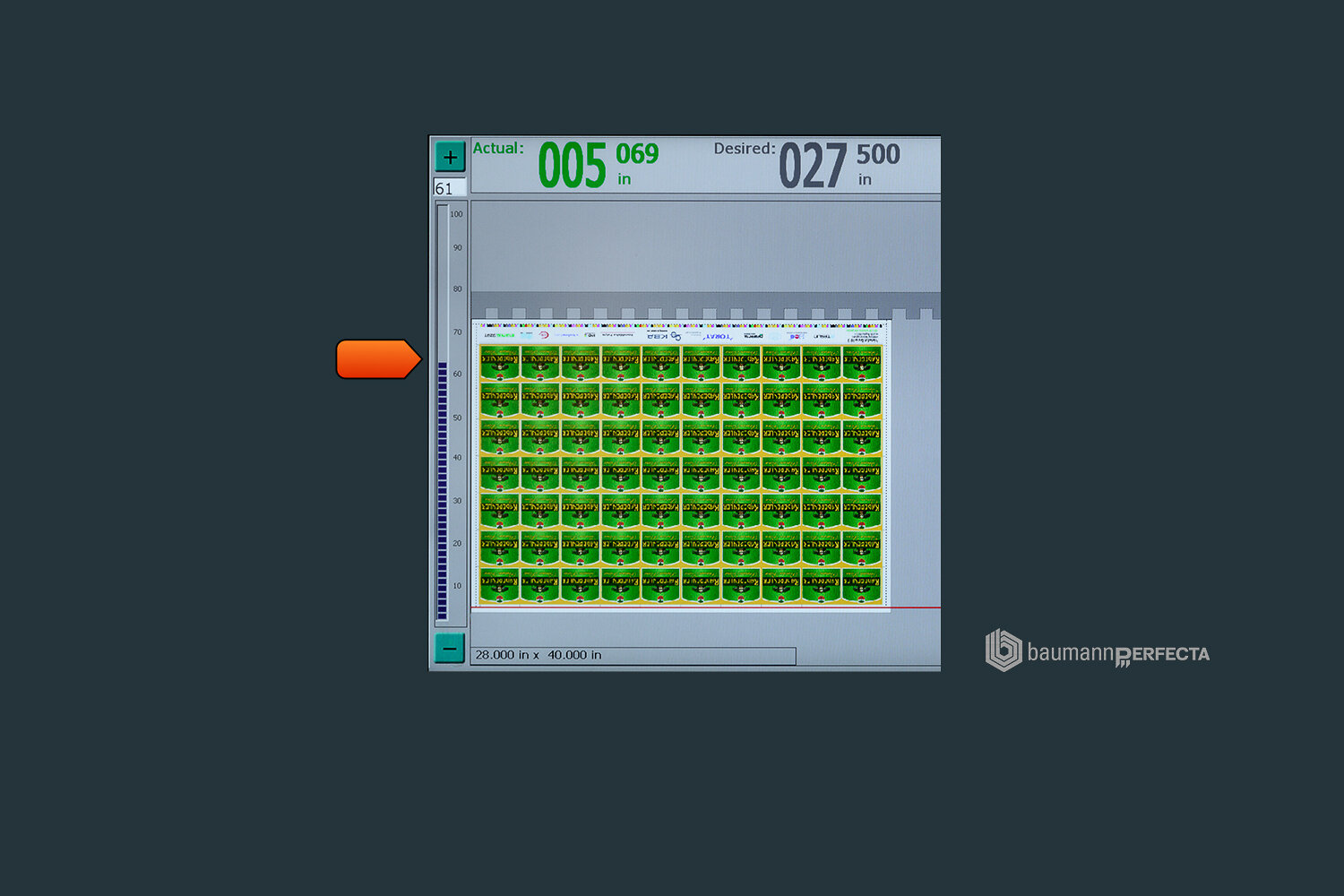

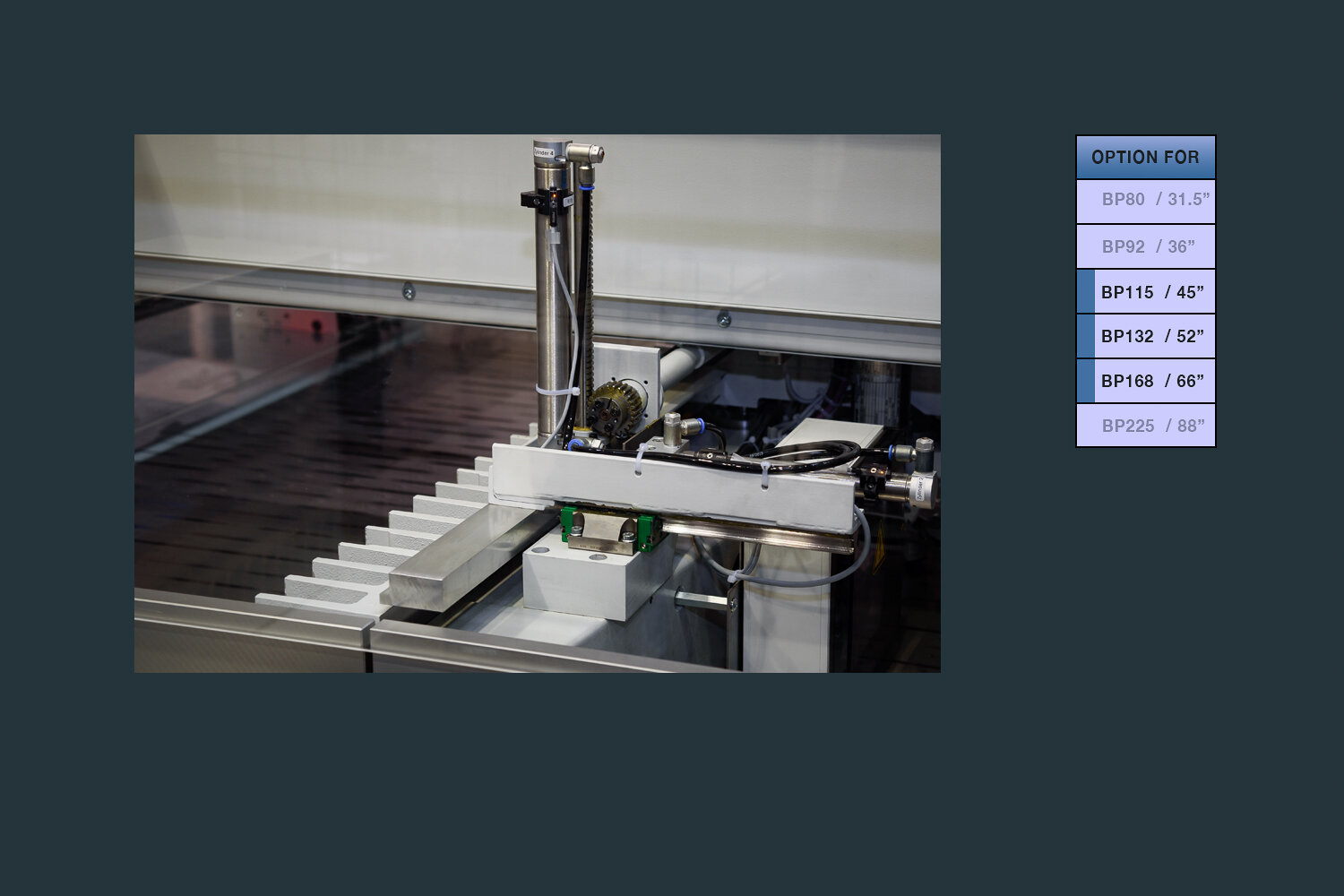

For backgauge speed up to 12” per second and a positioning accuracy of 0.0004” (0.01 mm) this system has an unmatched repeating accuracy.

With independent safety computer. All BAUMANN-PERFECTA high-speed guillotines bare the EURO TEST and GS Safety Certification Mark, awarded only by federal authorities after severe testing of safety, design, and quality.

Clamp pressure setting by finger touch directly on touch screen. In addition automatic adjustment of clamp pressure to each particular cut is a selectable feature that comes standard with every machine.

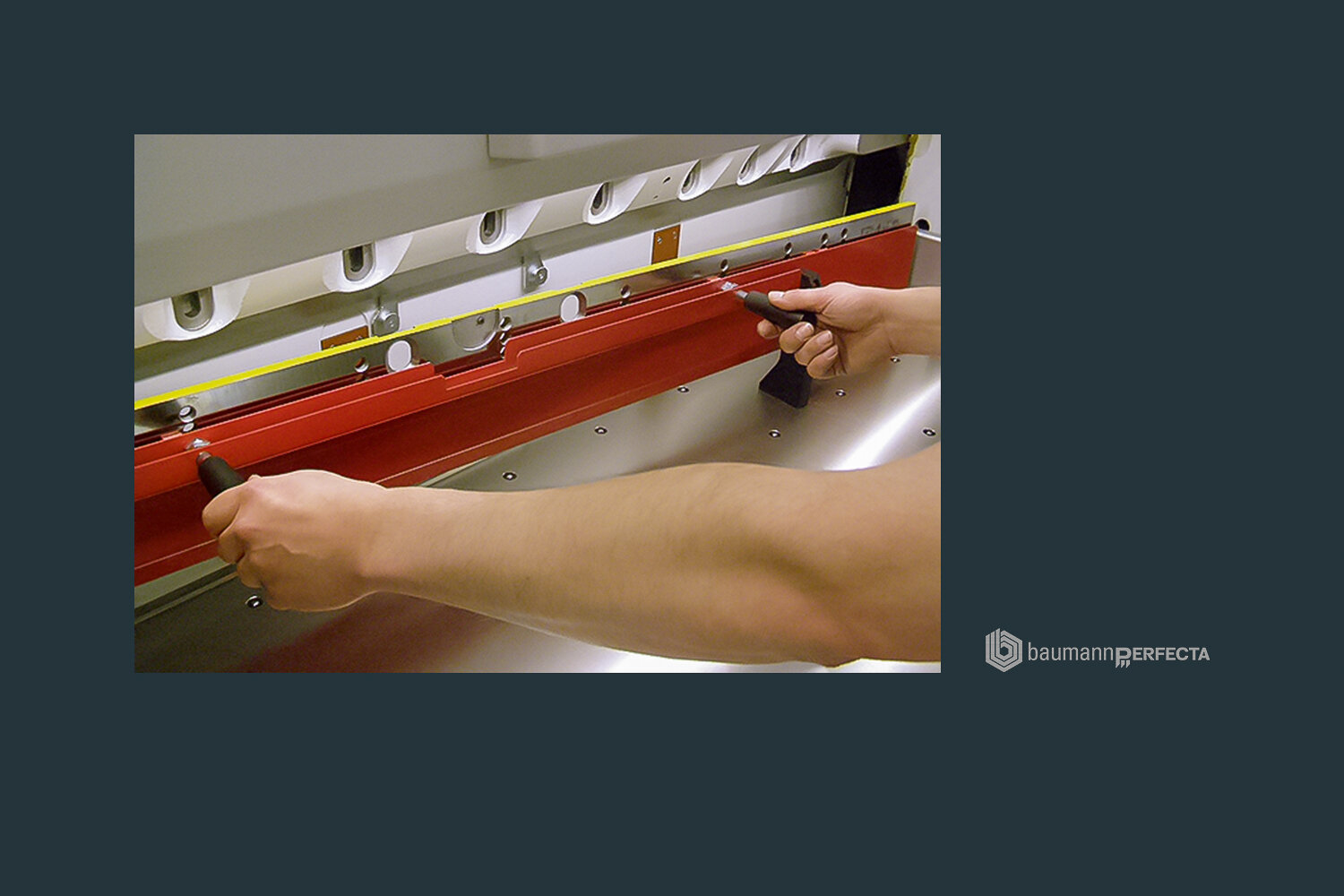

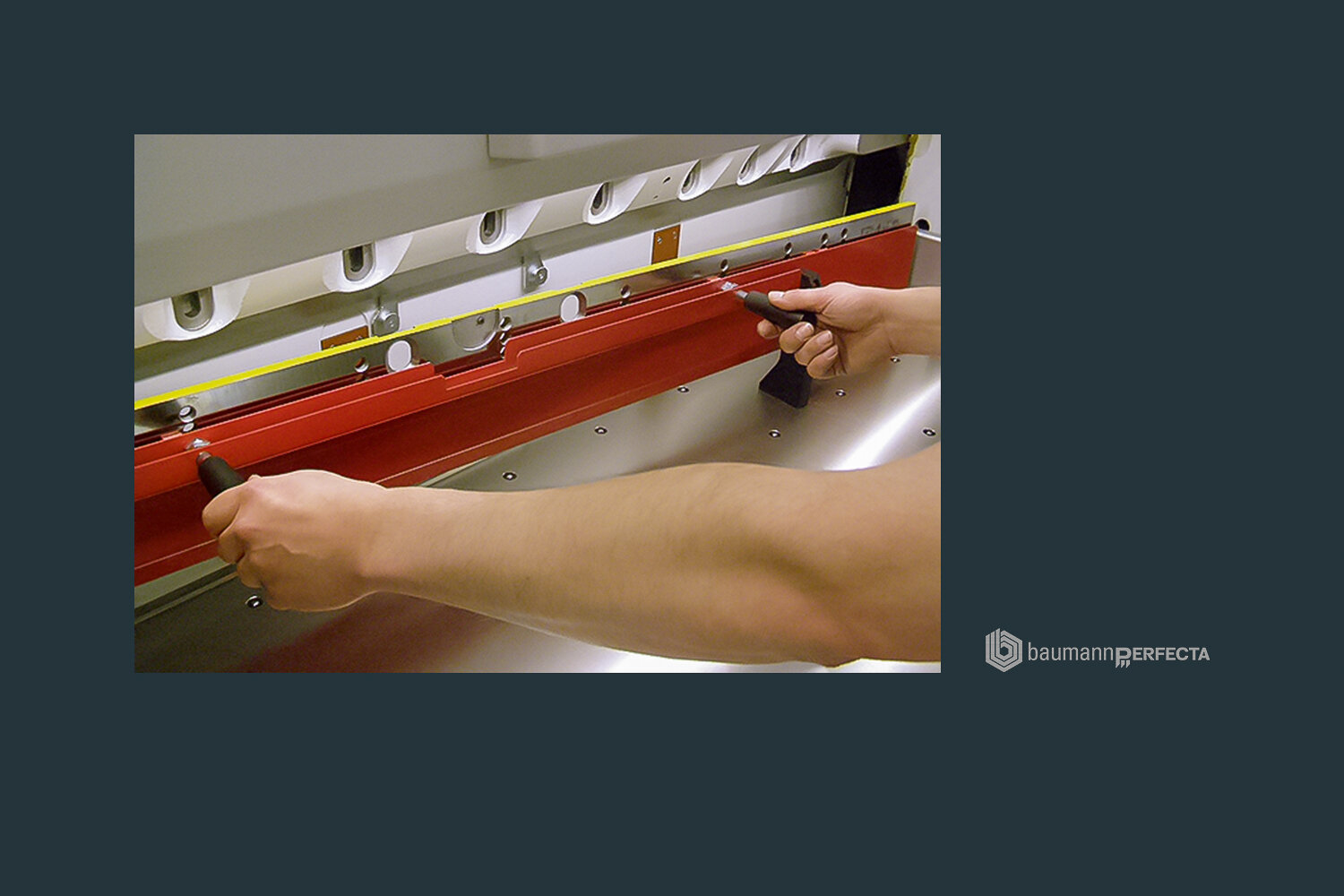

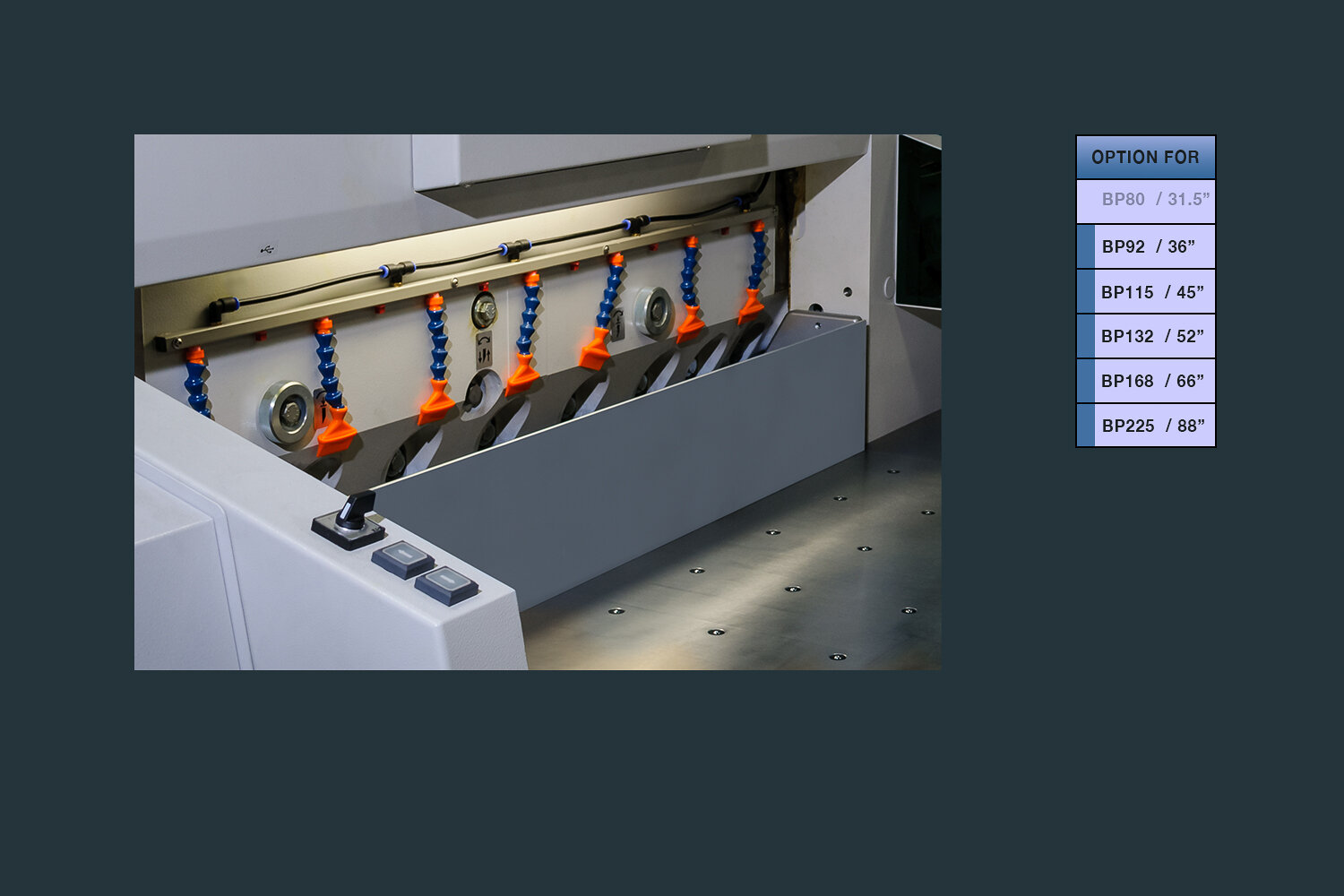

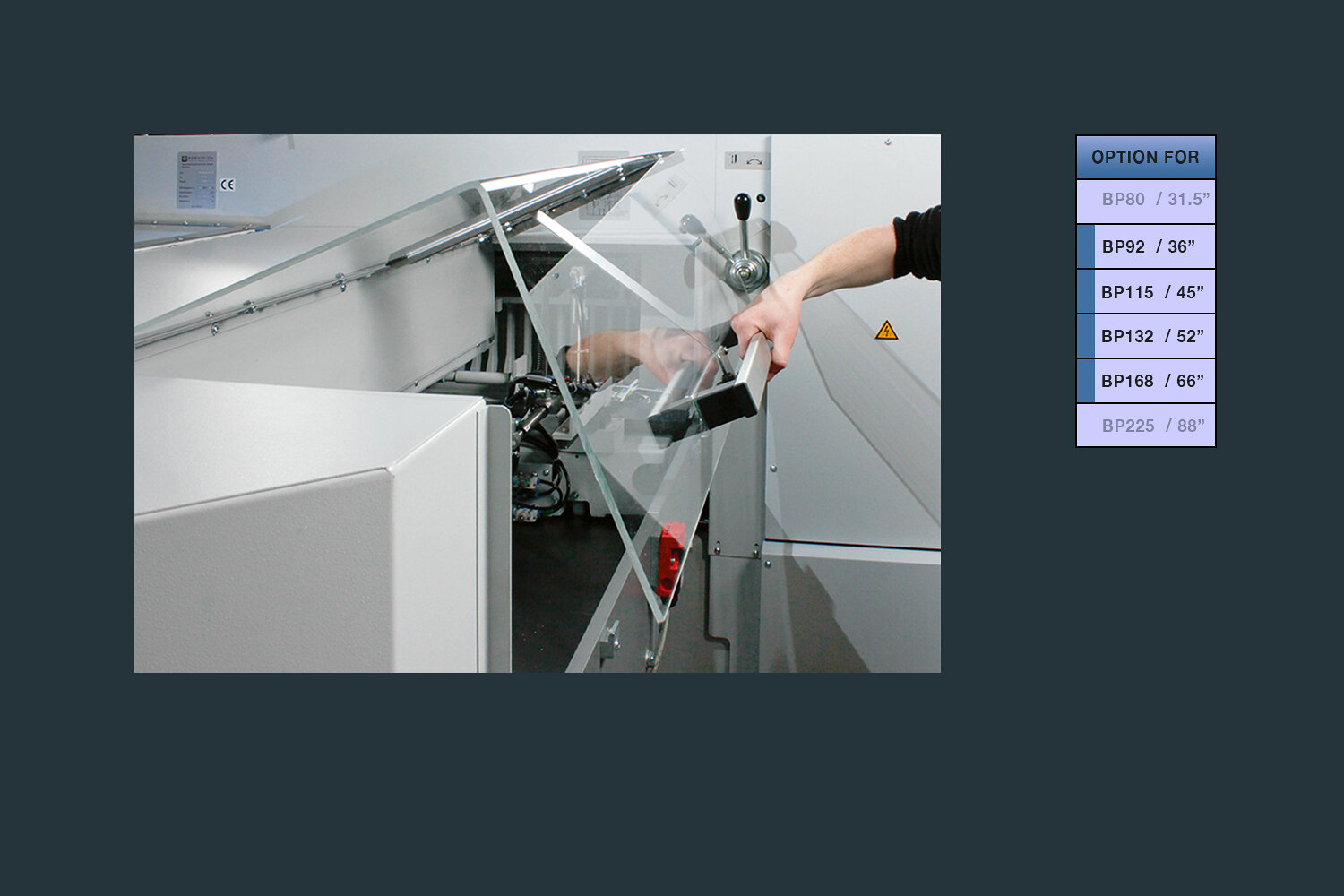

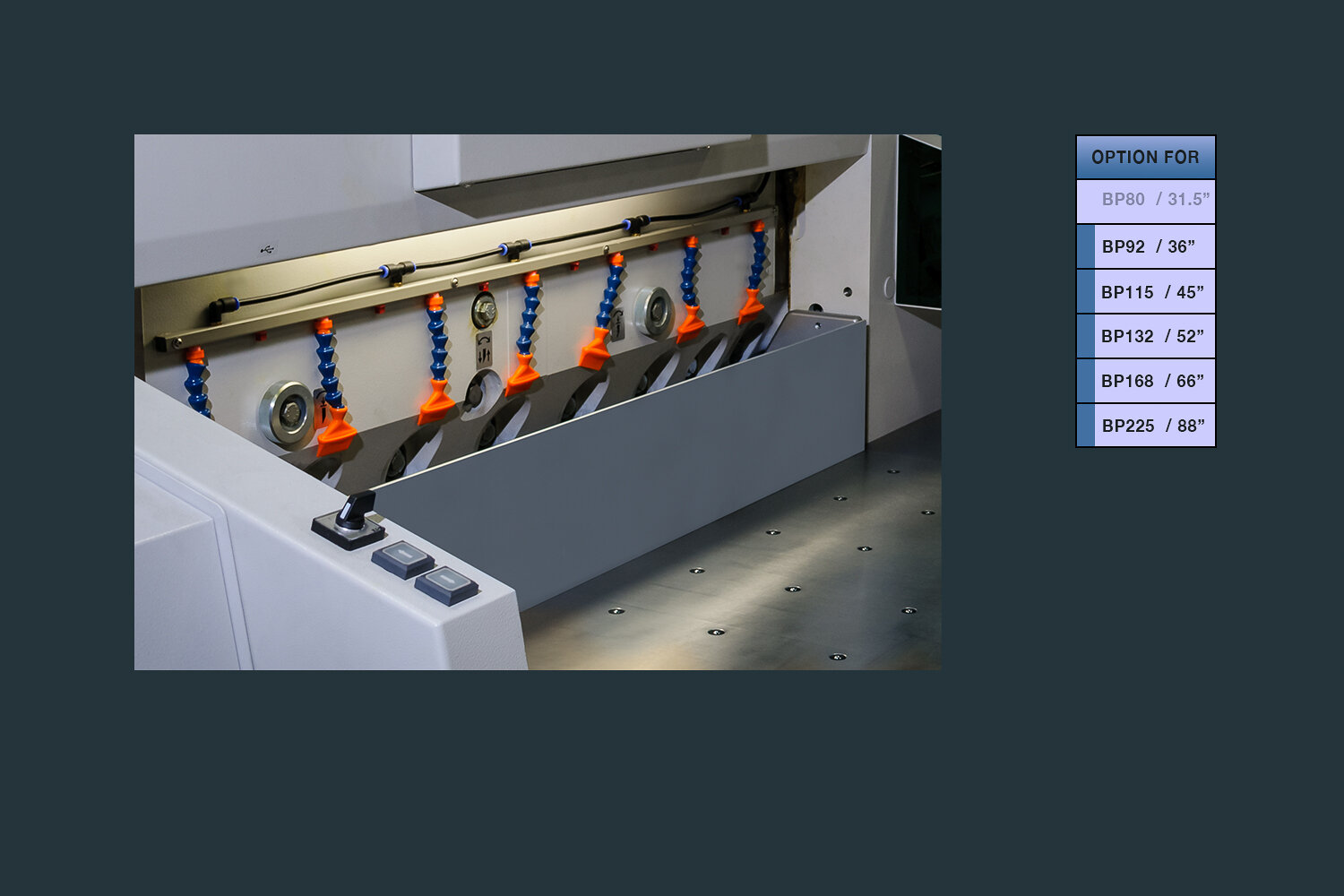

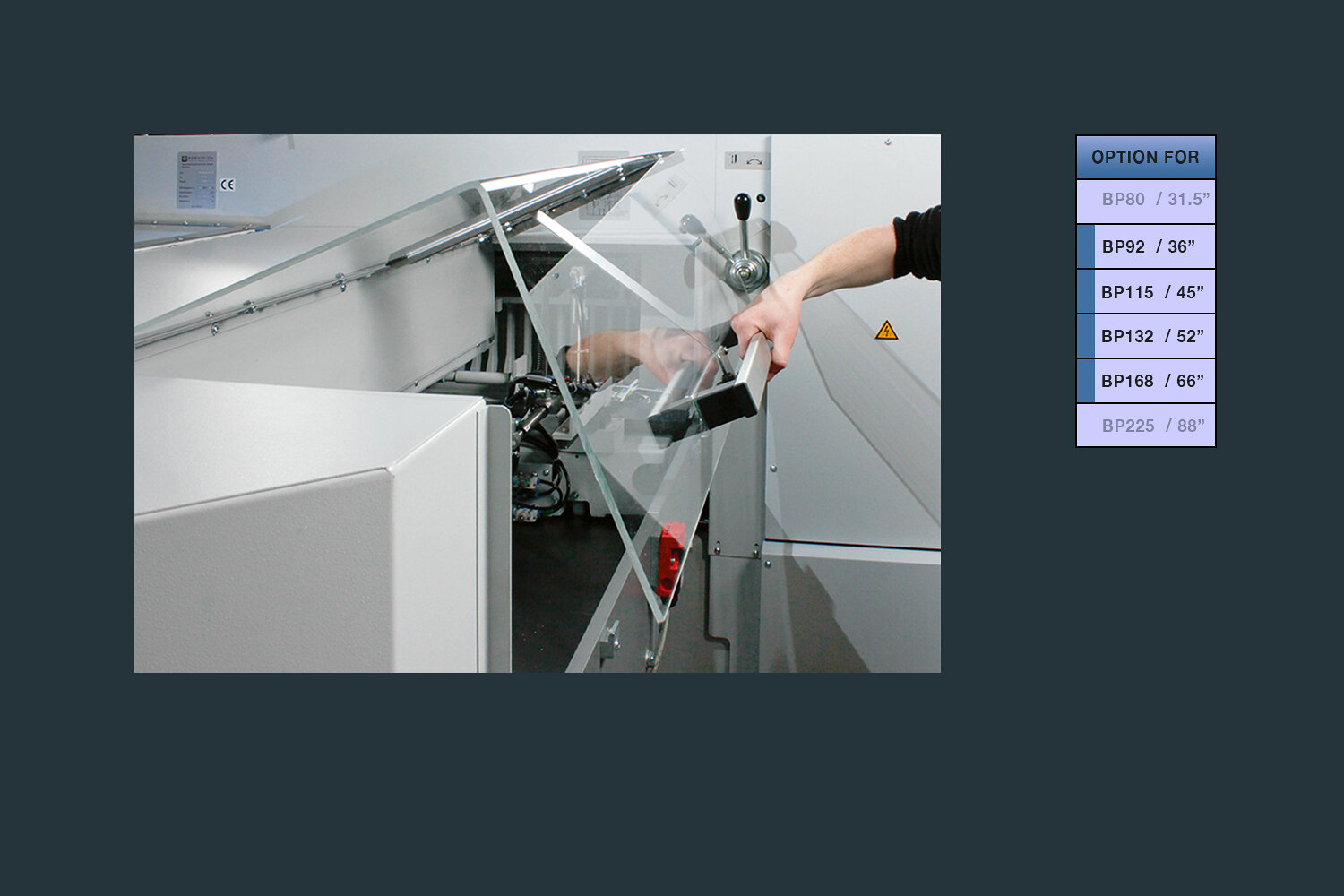

The PERFECTA knife change is the safest and fastest in the industry. All from the front side, no covers to open, and no expensive turnbuckle to deal with!

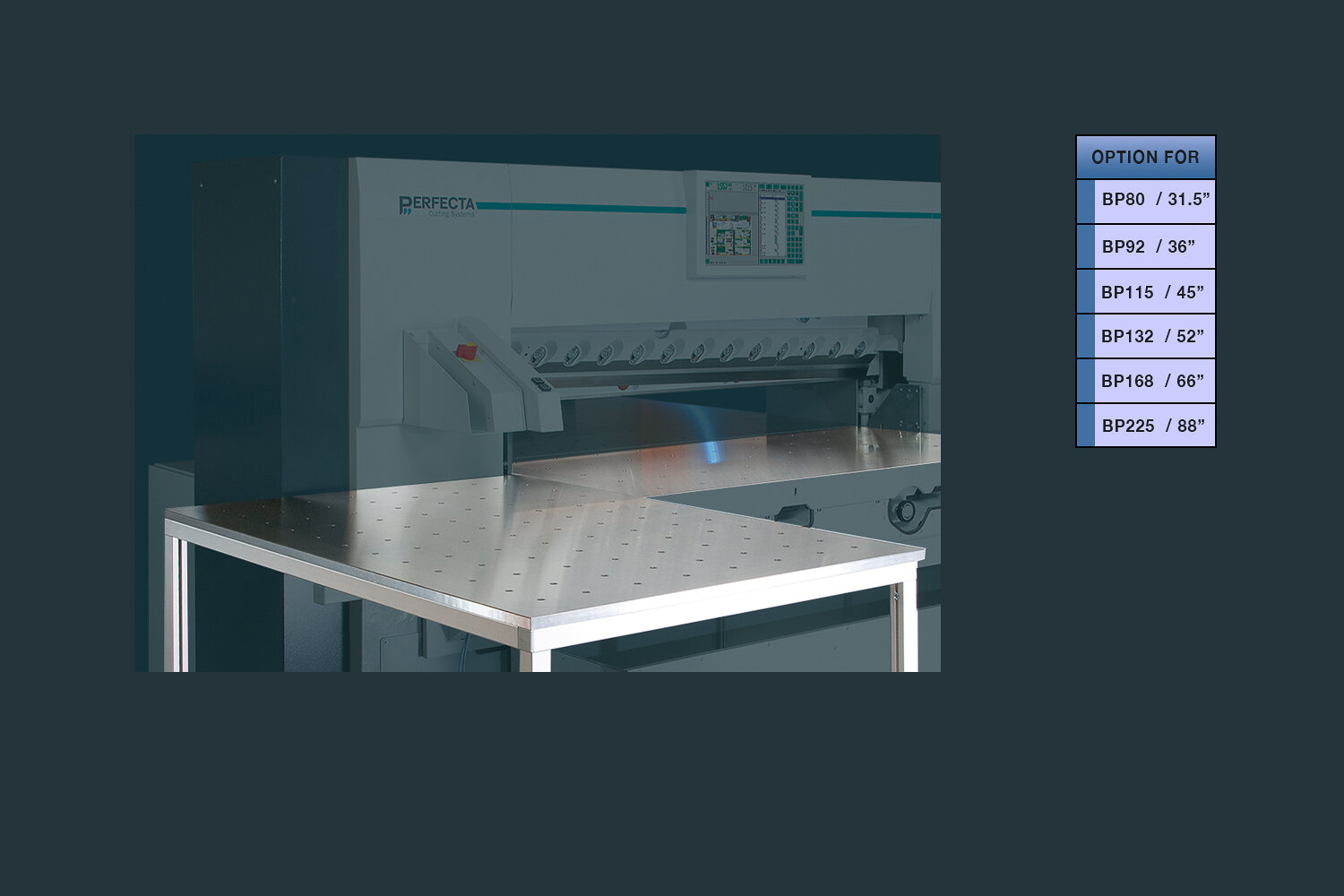

Rustproof stainless steel table top for excellent paper handling.

Knife guard, tools, and accessories are safely stored in one place, easy to access.

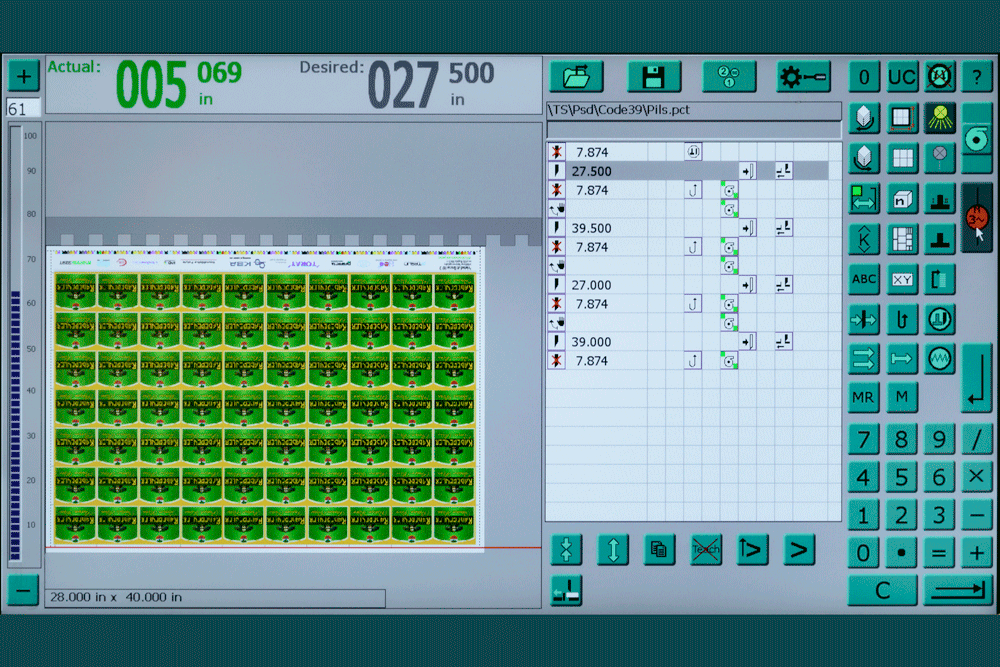

EASY CREATION OF CUTTING JOBS AND

STRAIGHT TO CUT (s2C) WORKFLOW

OPTIMIZE YOUR CUTTER WITH OUR OPTIONAL EQUIPMENT

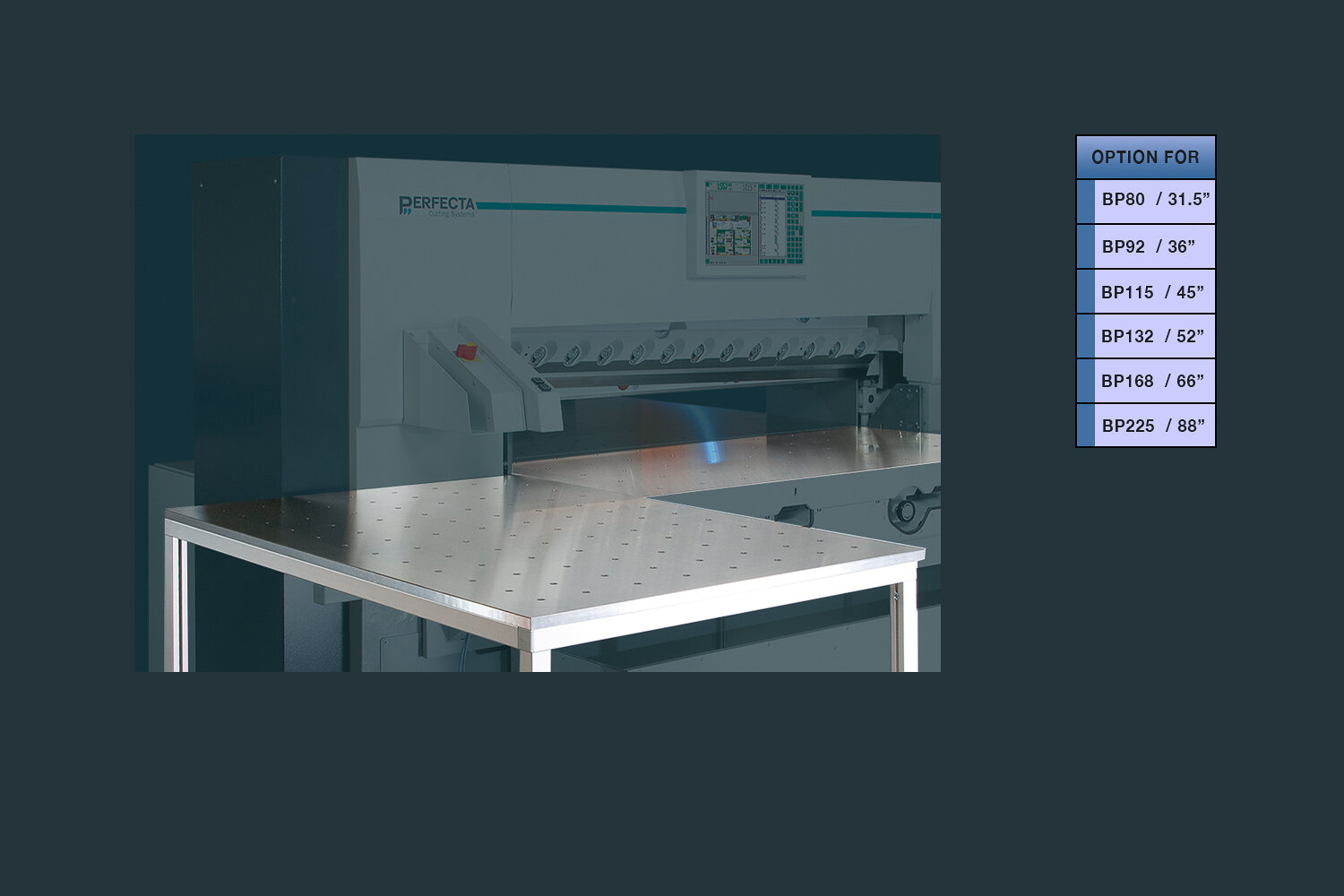

Do you need more space at the front of your cutter or want to expand with a packing area? We offer air side tables with stainless steel table top in many different sizes and transfer corners or trapezoid tables that fit your particular workflow.

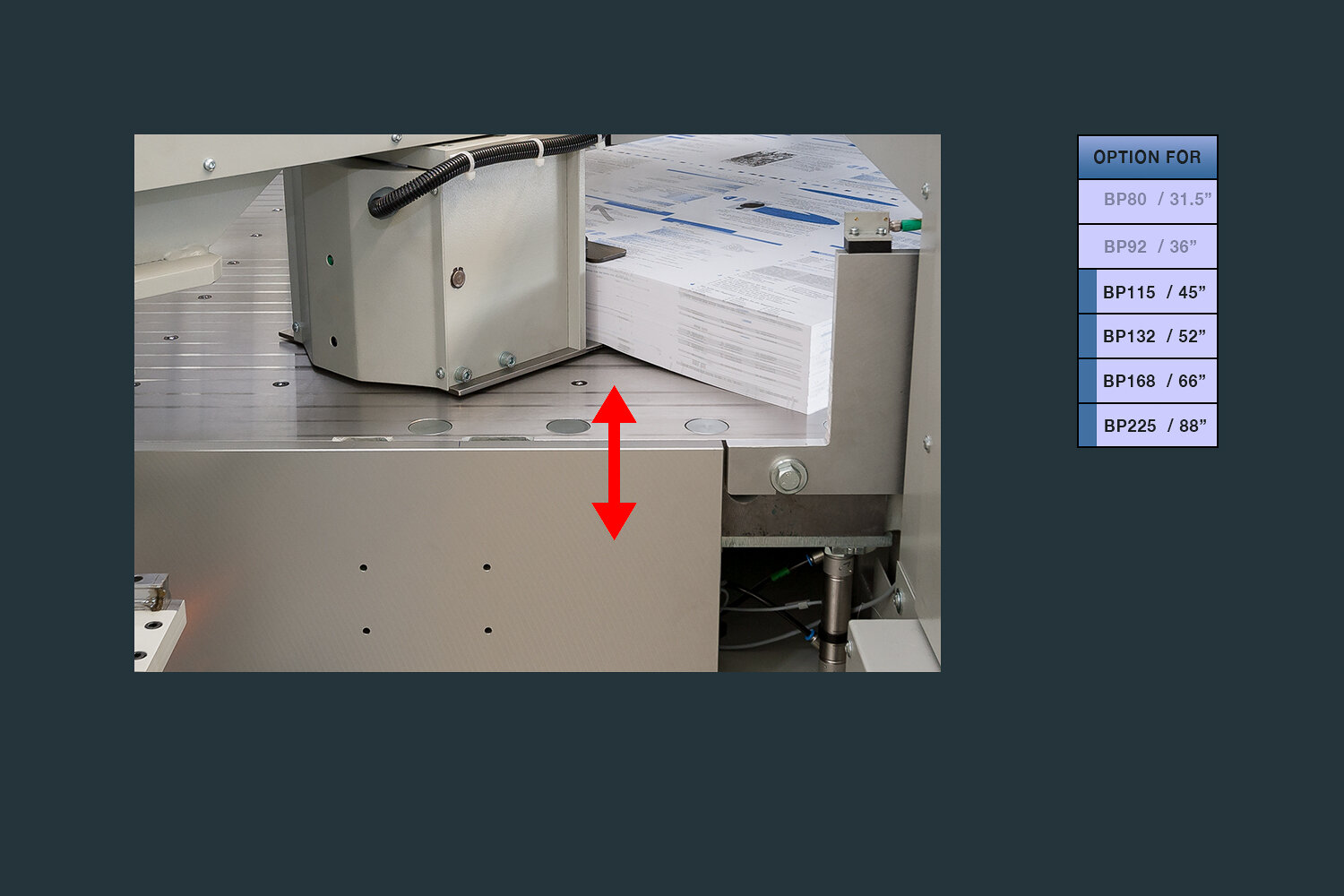

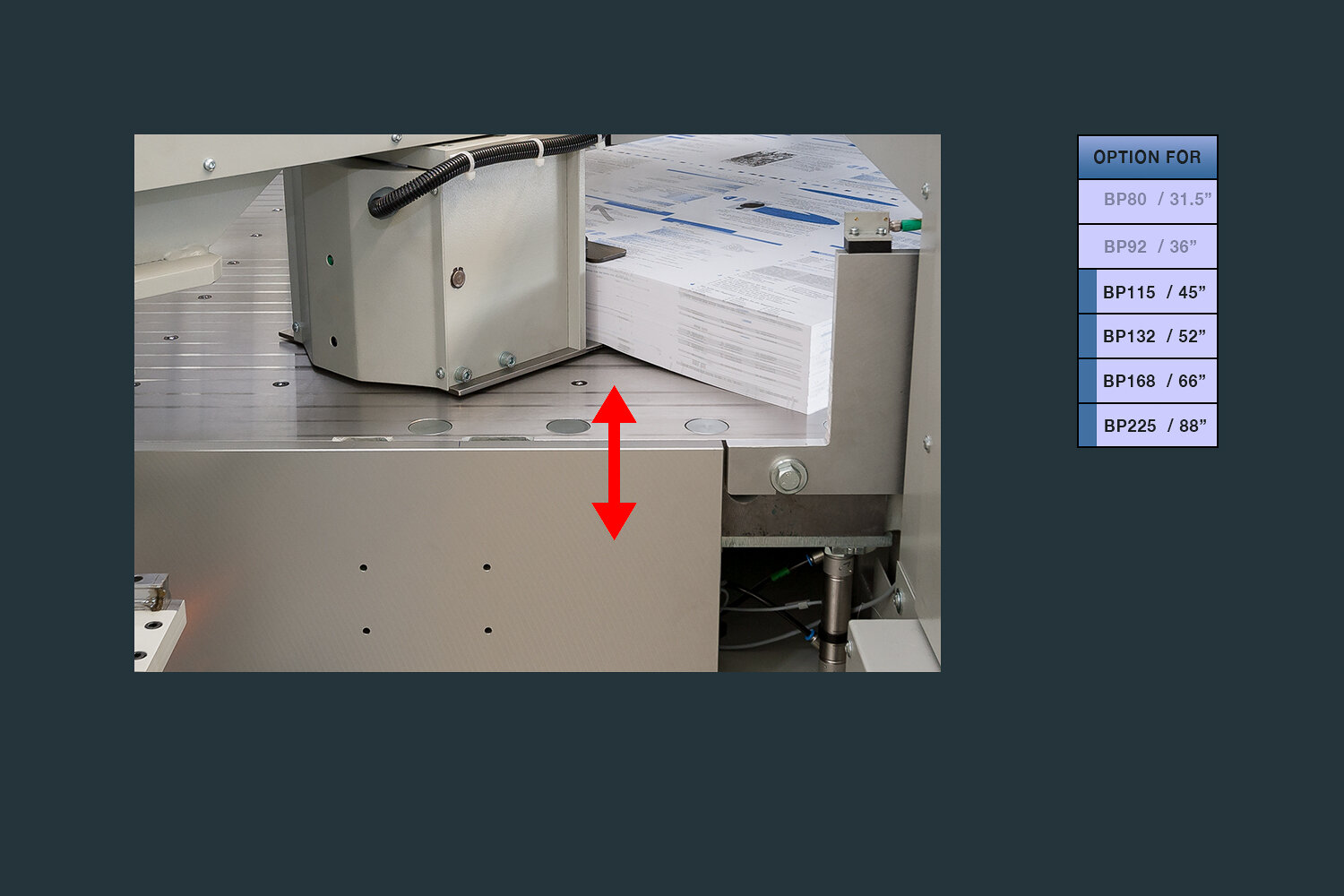

With servo-driven fast and smooth table opening and closing. Bed lowering option for delivery of smaller products onto a board sheet. The AWR boosts productivity up to 40%.

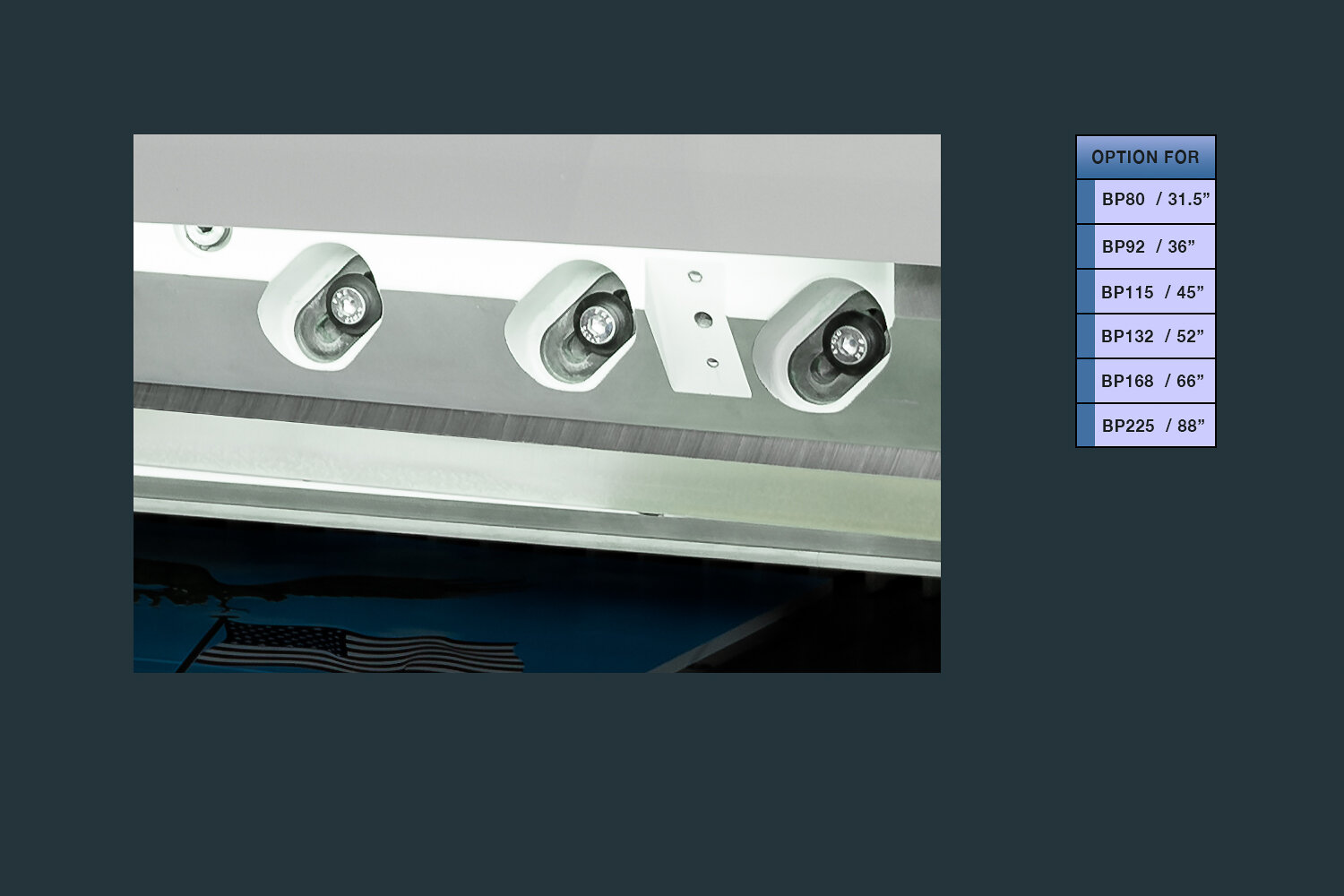

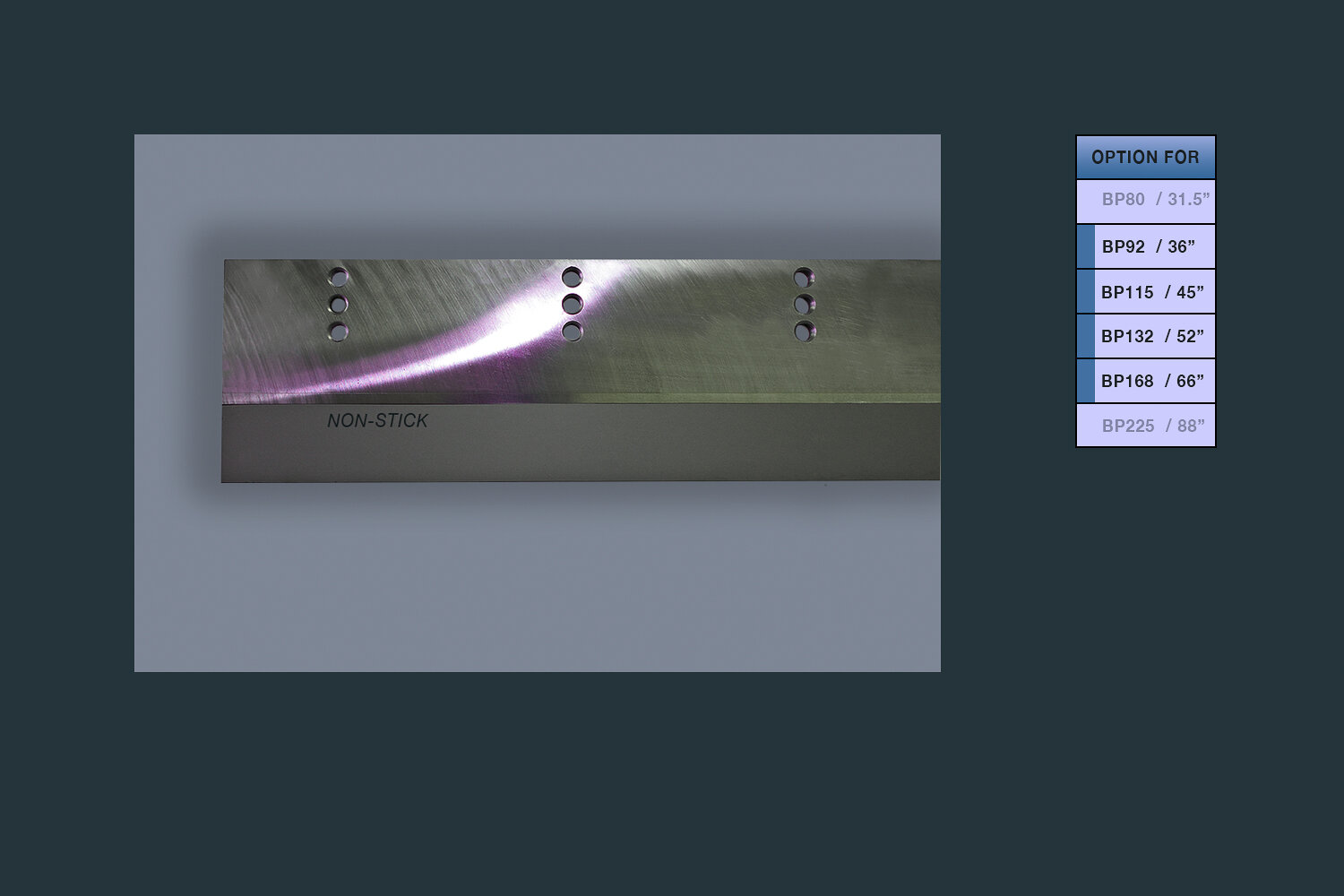

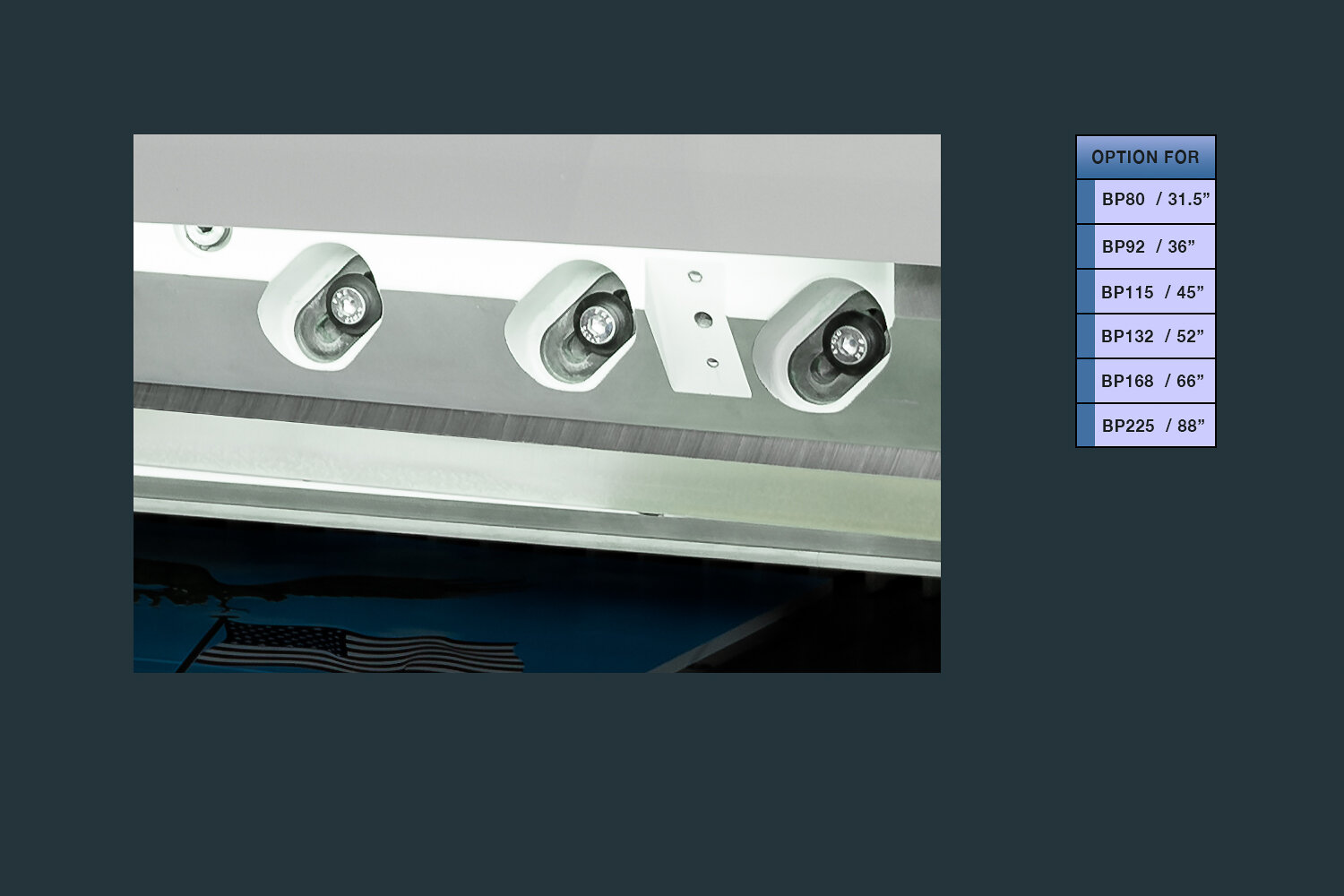

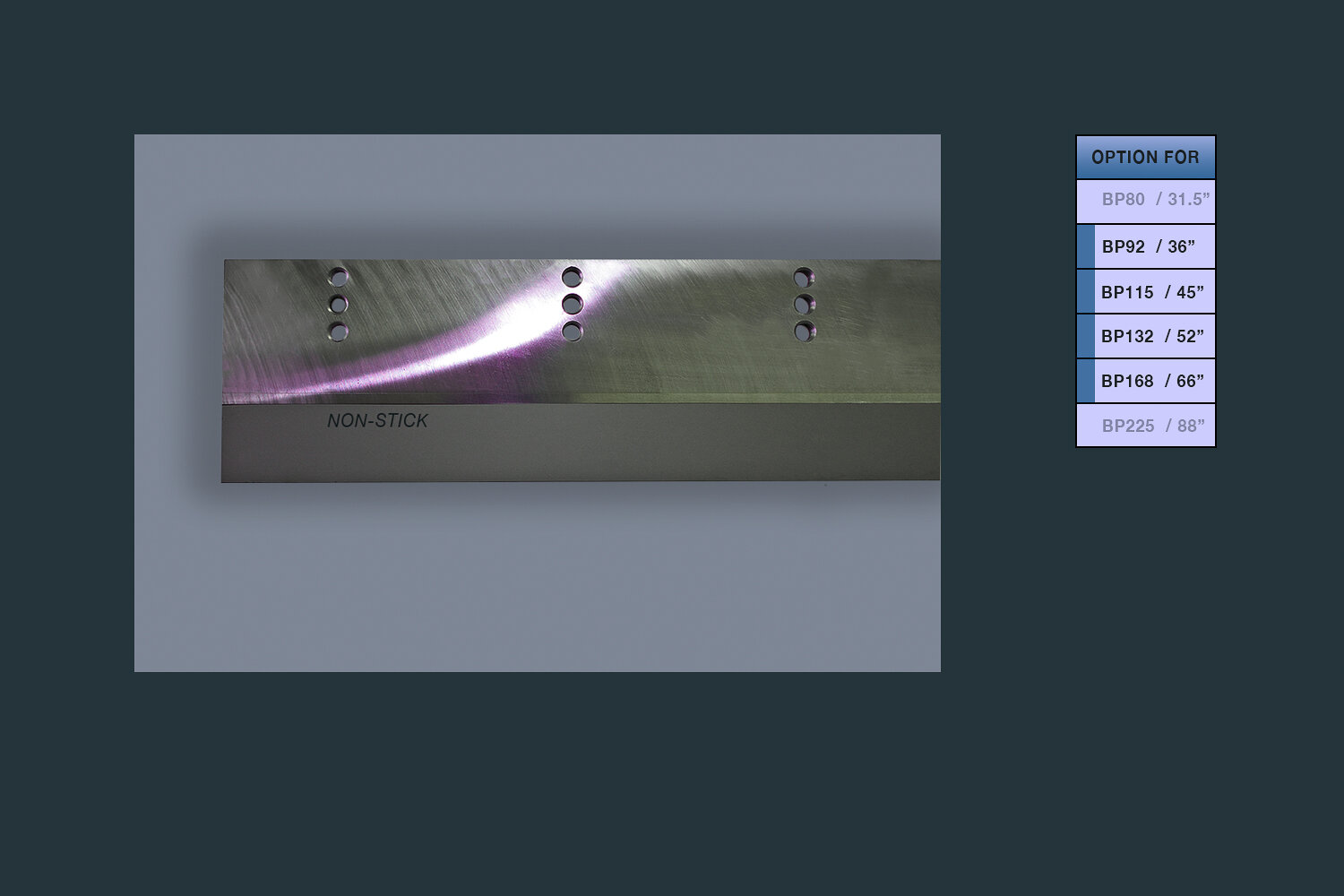

Prevents statically charged cutting scrap or plastic from sticking to the knife. Makes the waste removal even faster.

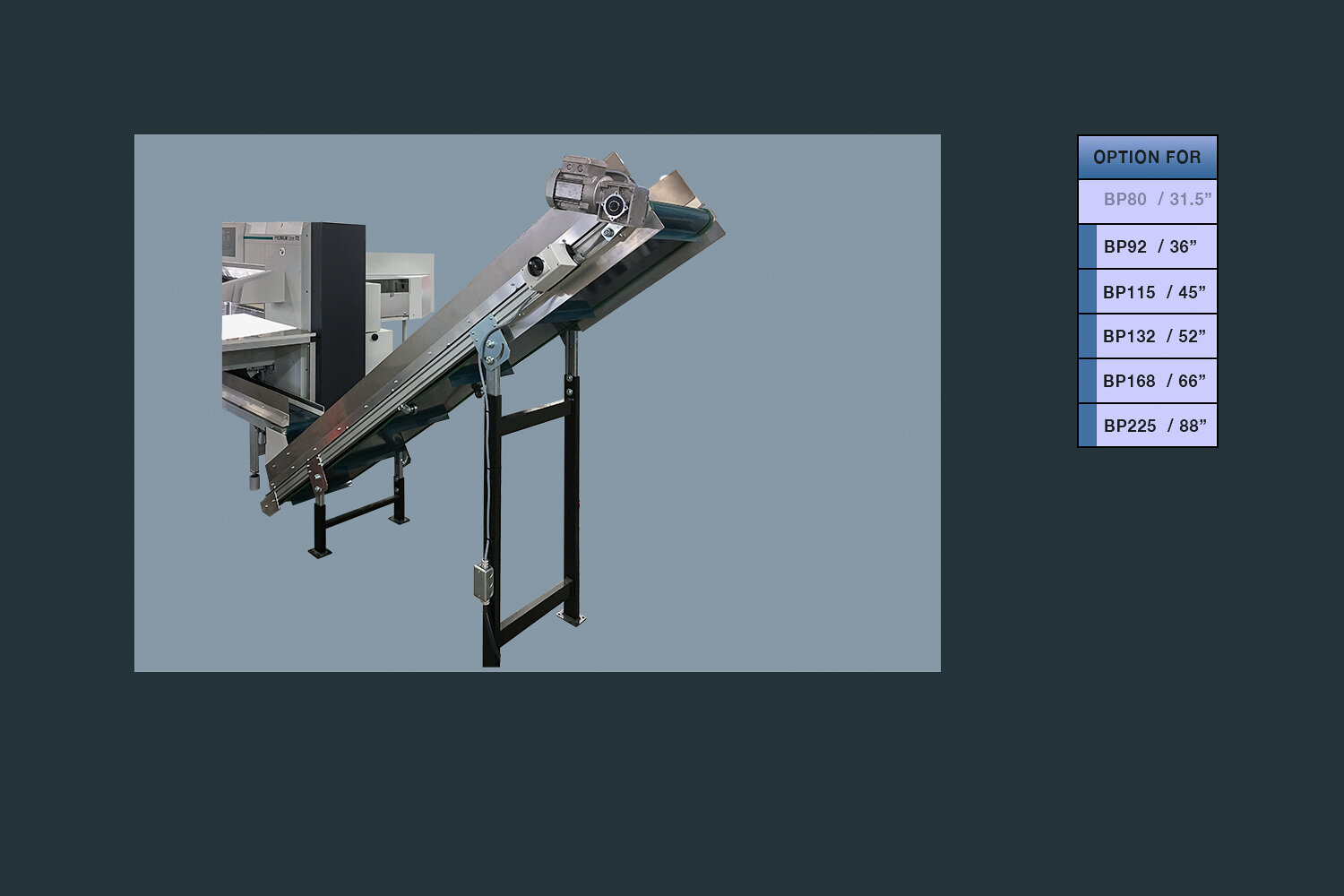

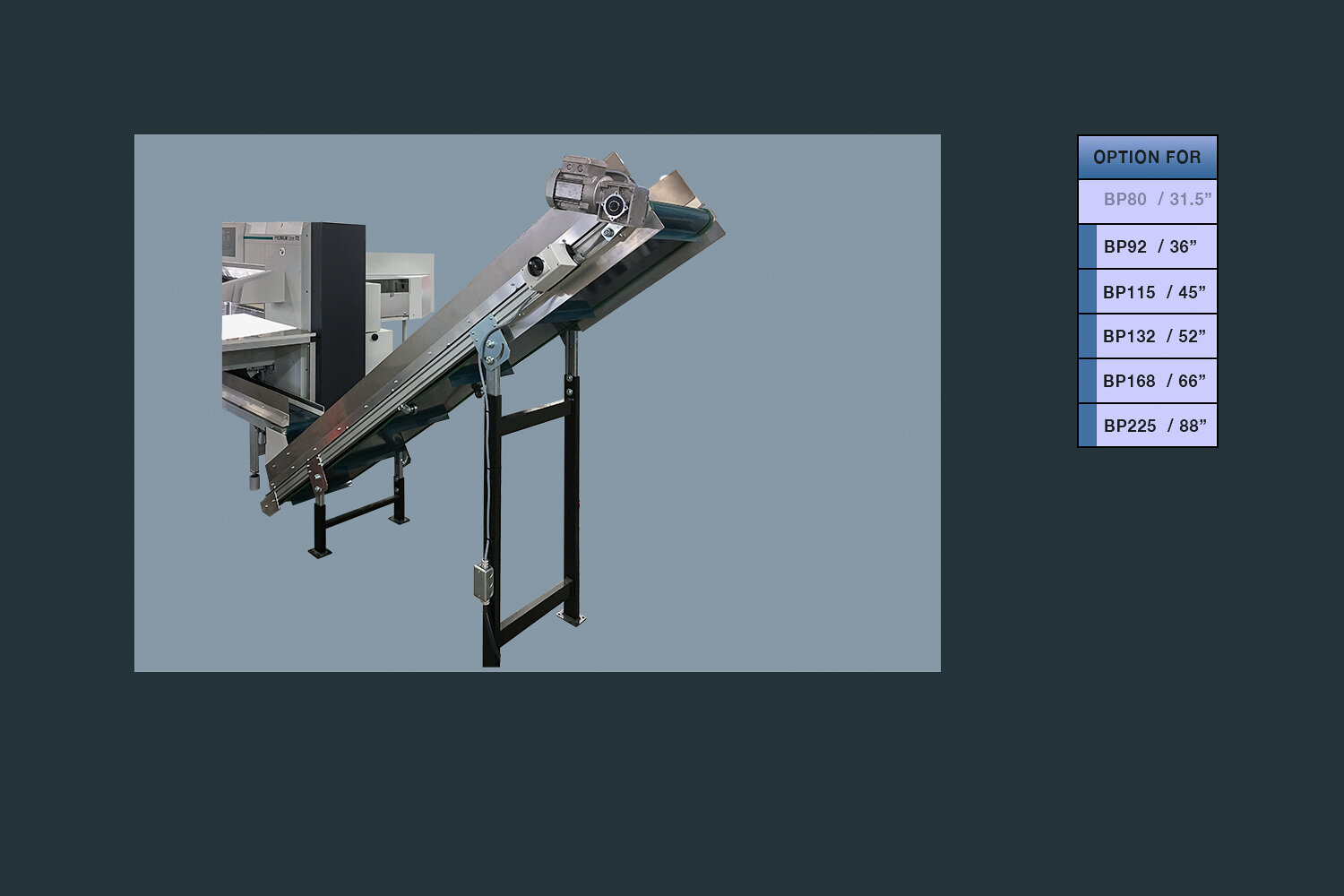

For removal of cutting waste to either side of the cutter or in a 90º angle to the back or front. We can fit your floor layout.

High cutting precision and considerably longer service life will help you to increase cutting performance and reduce grinding costs in the long run.

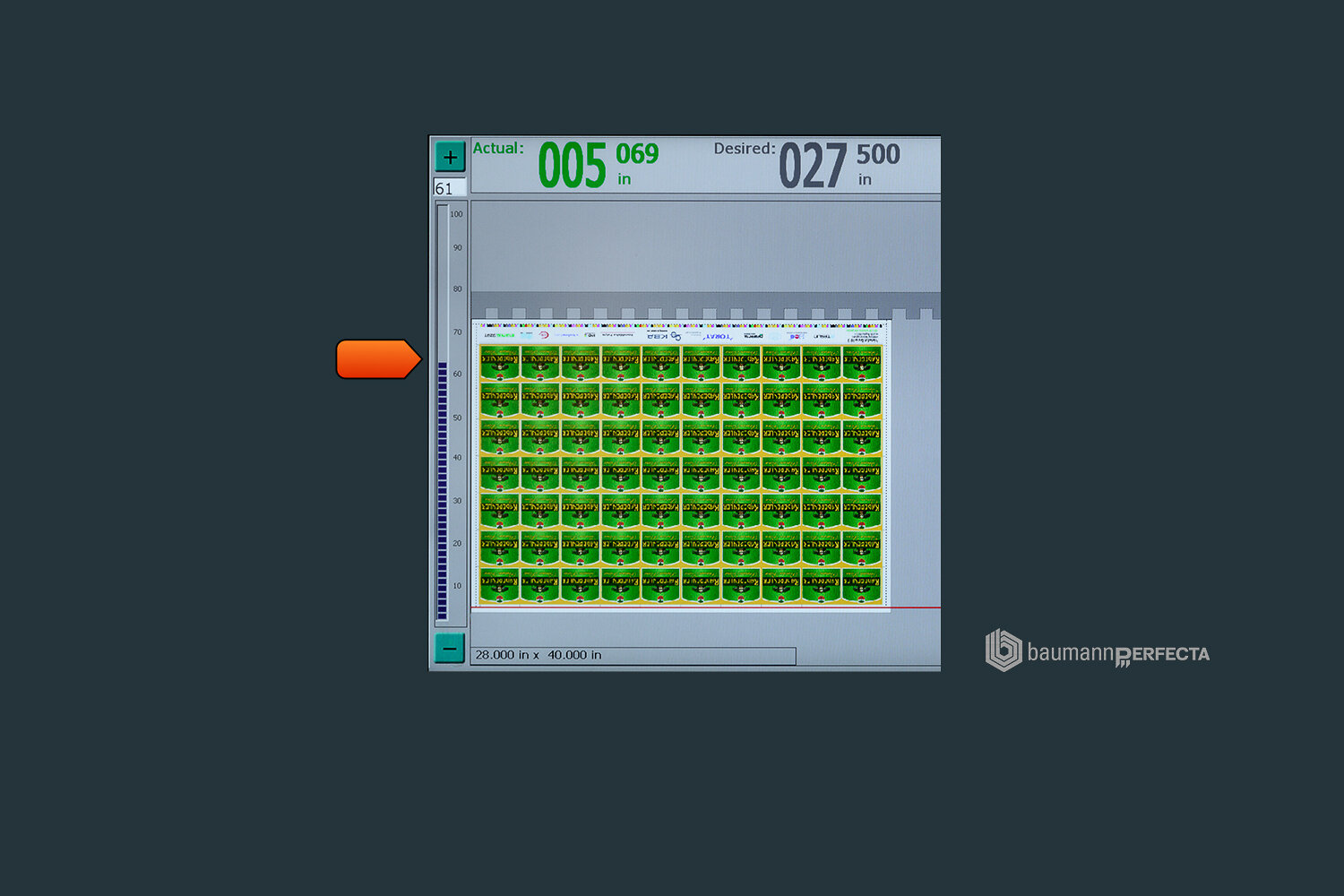

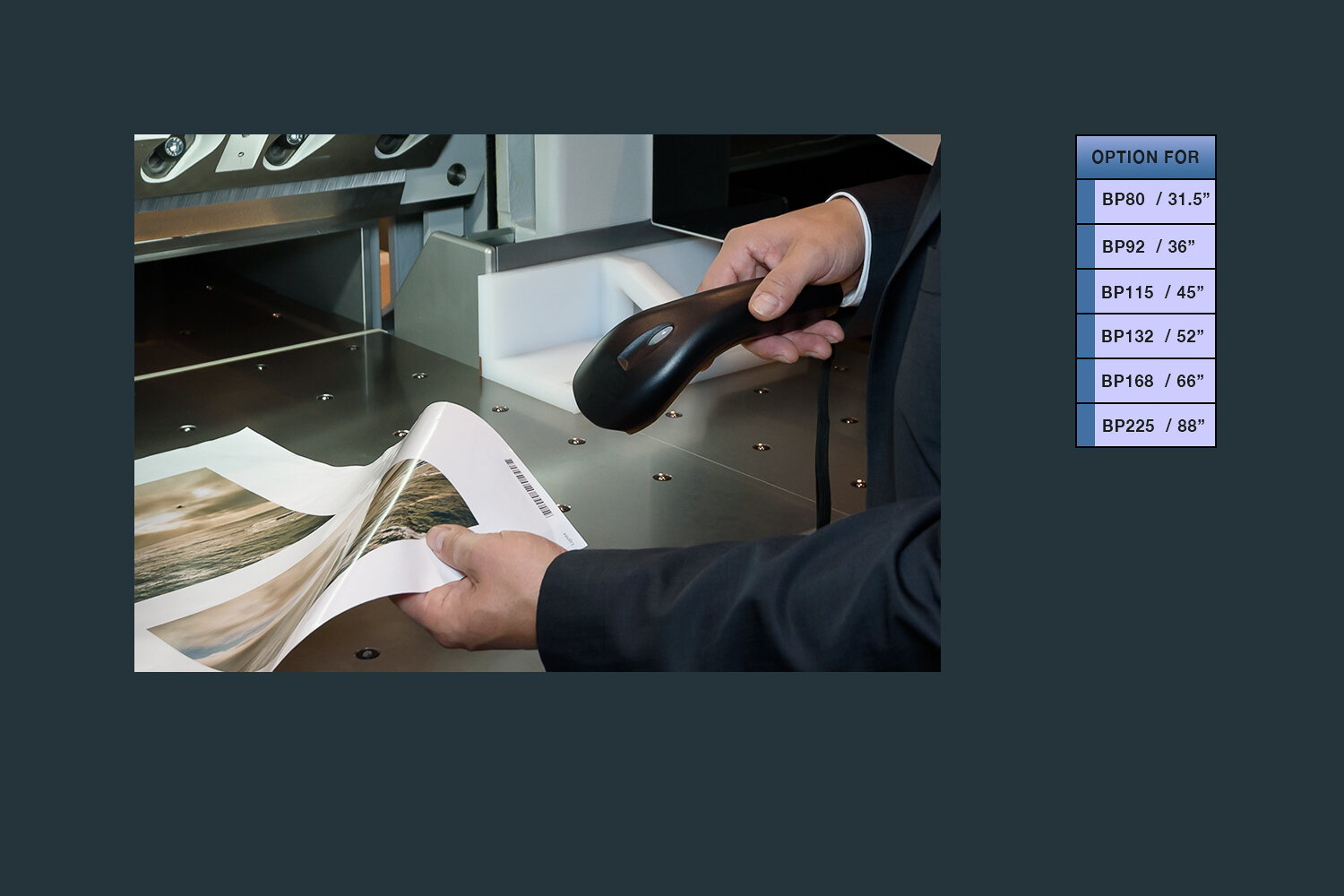

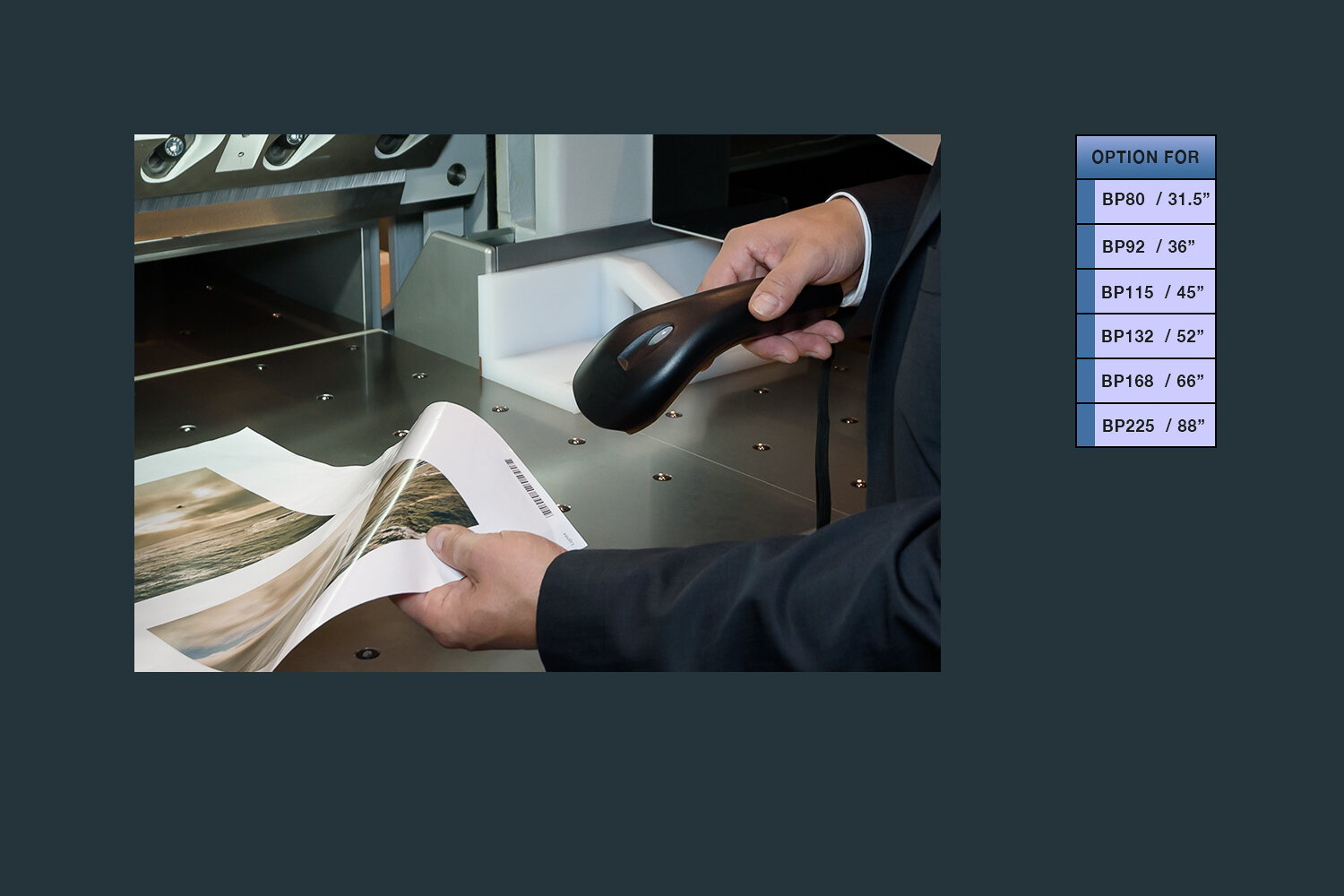

Loads automatically the correct cutting program for the job. No CIP- file required.

The S2C is the most versatile solution to extend your digital workflow to the cutting process.

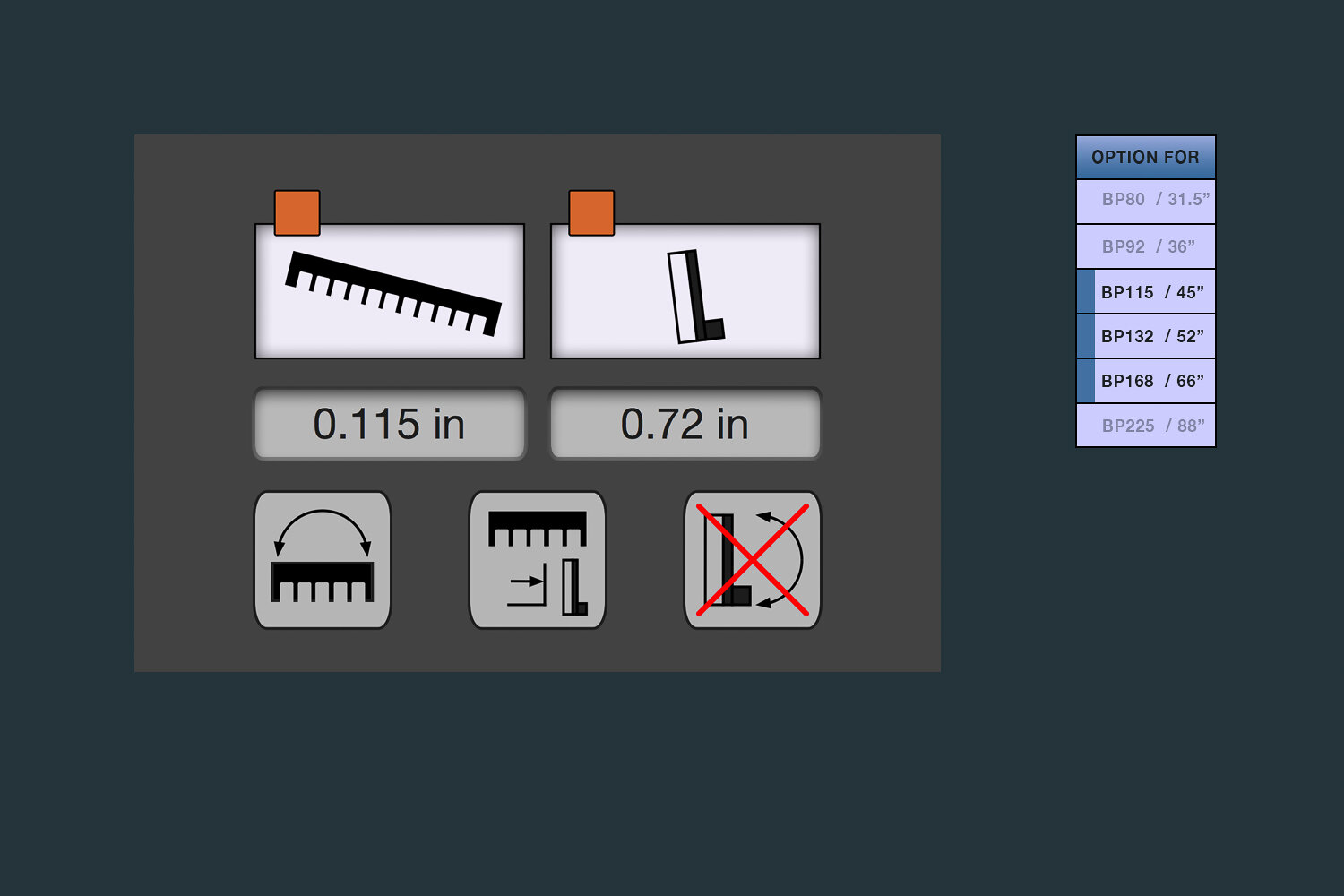

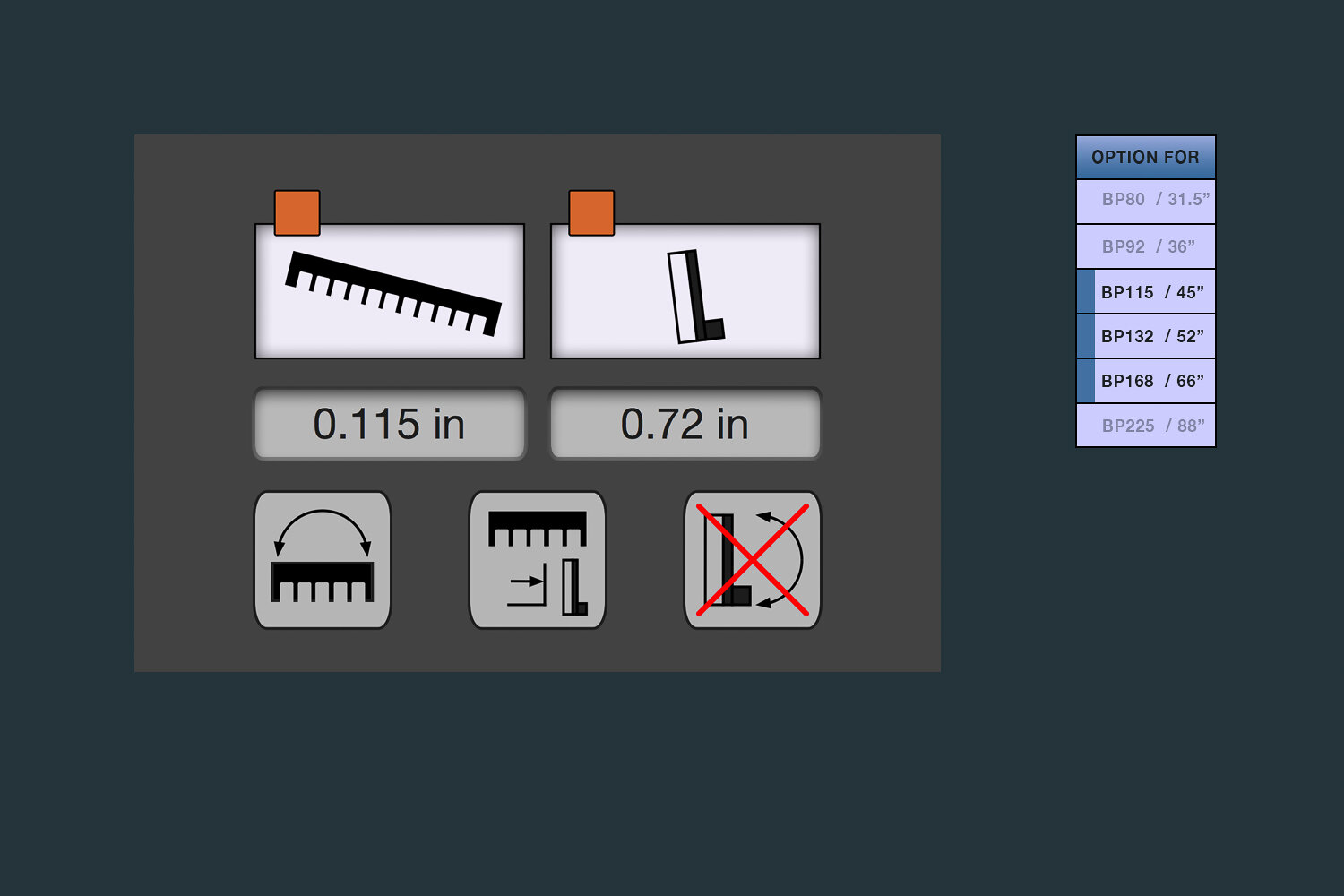

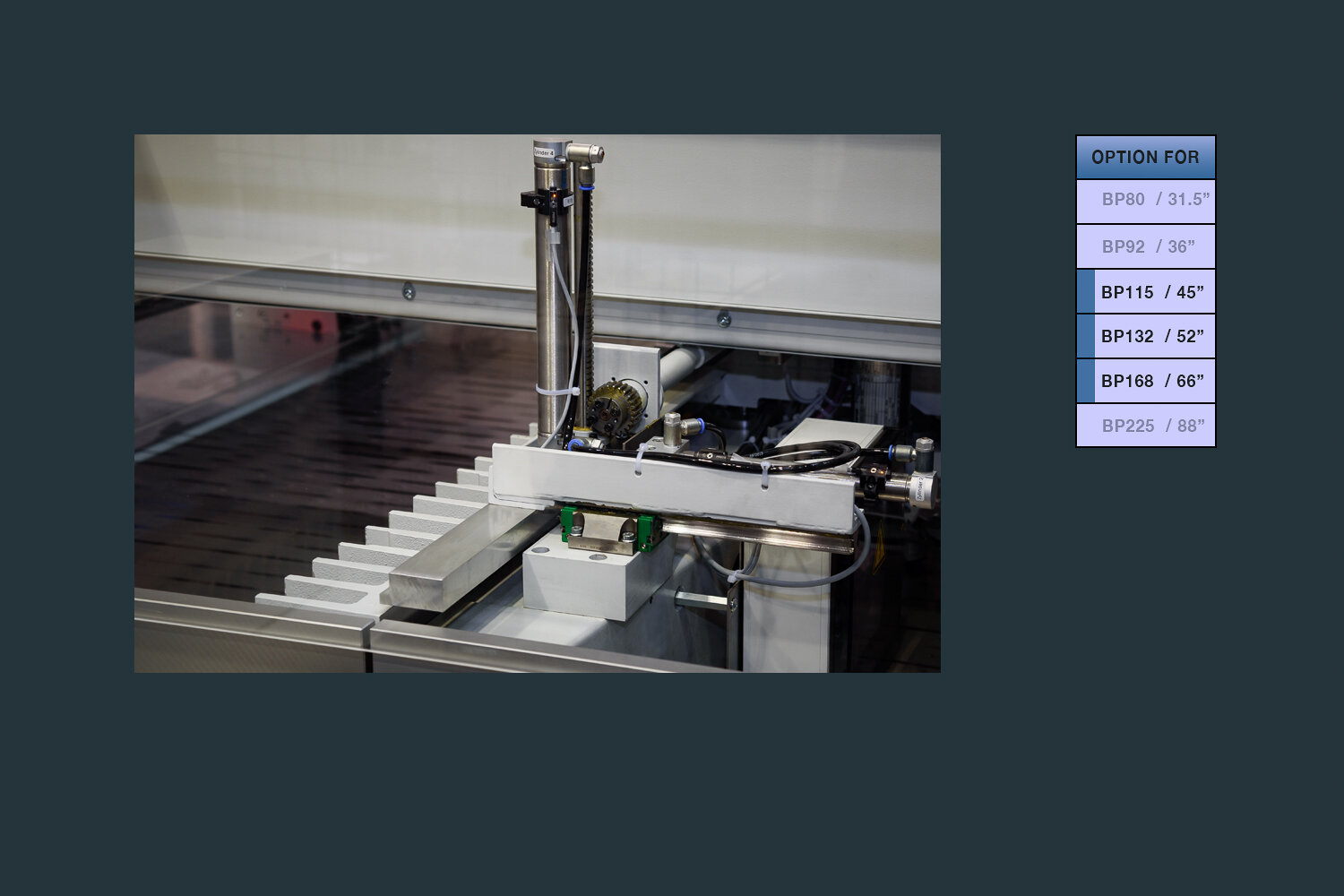

For compensation of a skewed print on the sheet. Settings and adjustments are made on the touch screen of the cutter.

For compensation of a skewed print on the sheet and cutting deviations caused by over- or undercutting. Adjustments are made on the touch screen of the cutter and the swivel or tilt function can be integrated into cutting programs.

For cutting pressure sensitive material, like foam board or corrugated material. If the device is activated, the minimum clamp pressure is lowered to a range that allows to cut such material without damage.

Activated by push of a key, this feature limits the clamp stroke. After each cut the clamp stops its upstroke about 1” above the material. This allows for extremely fast cutting, especially of material that needs to be cut as a single sheet or in low stacks (felt, fabric, leather, some plastic or fiber board).

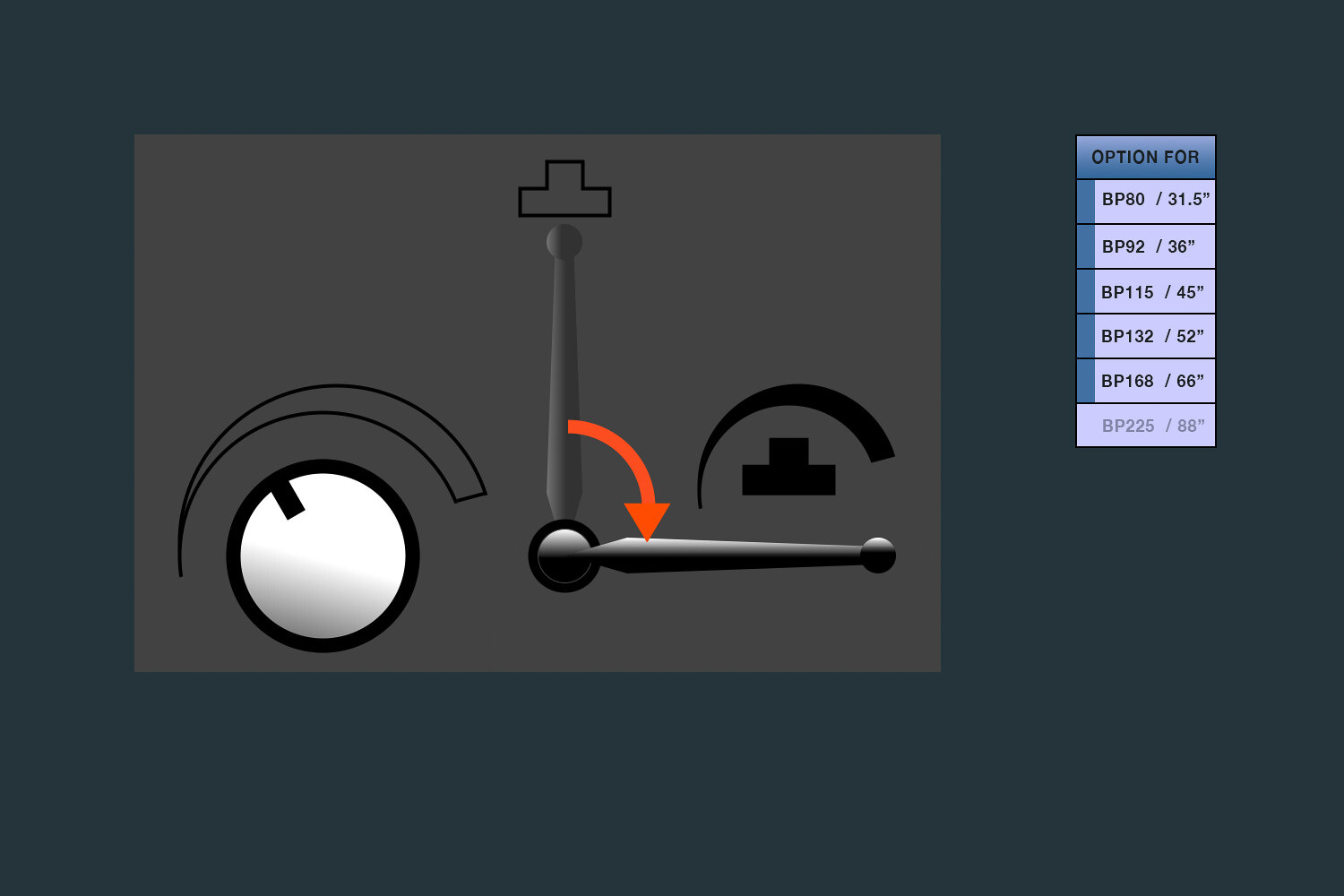

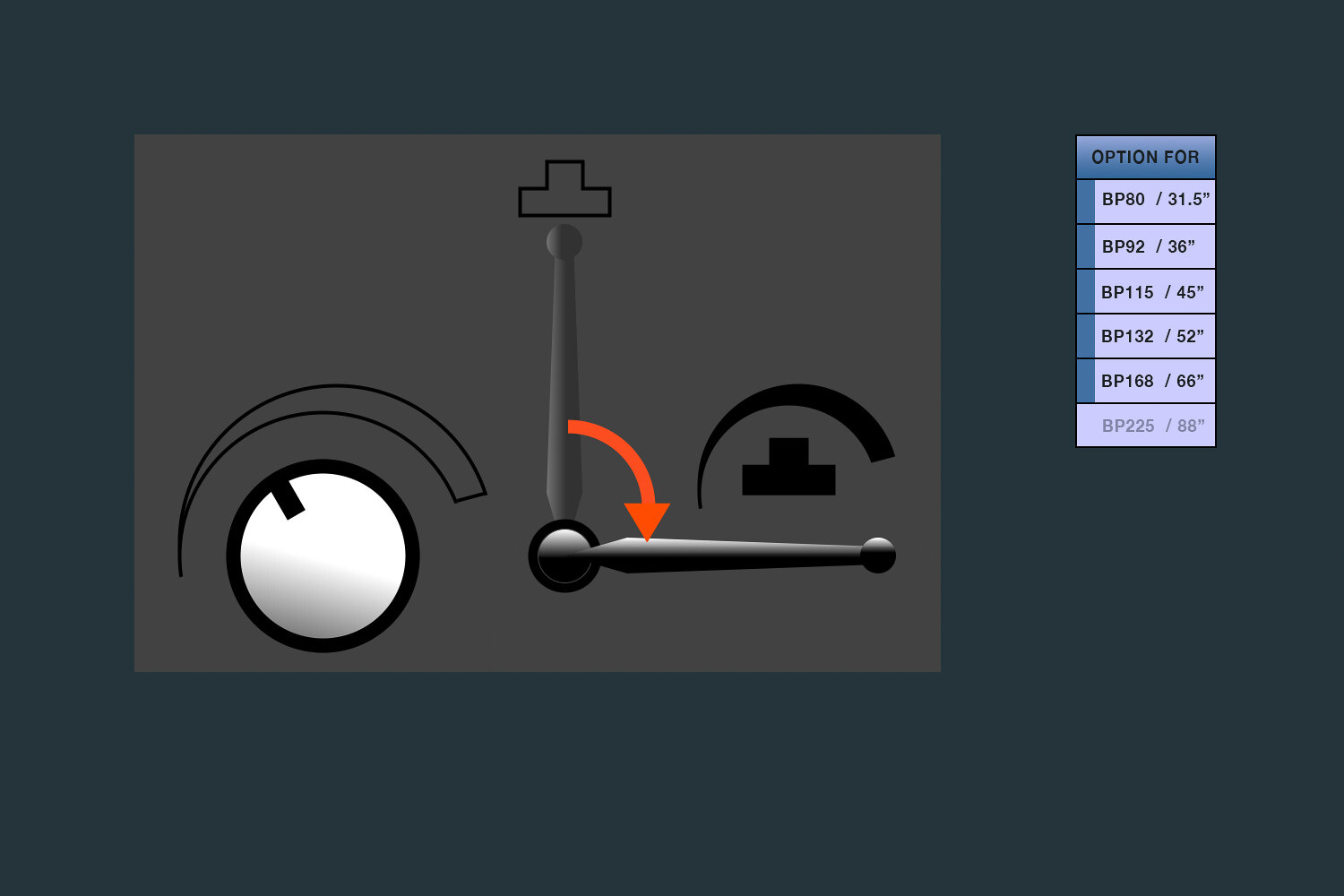

For loading or unloading the cutter via the rear table and for fast automatic turning of the paper lift. Available for left and right hand side.

For exact alignment at the print marks of concave or convex sheets.

Easy access for cleaning the rear table or the knife from the backside but still retaining a maximum of safety. If the guard is open for cleaning, the cutter is locked. A useful option not just for cutting of glued products.

Prevents curling of sheets at the backgauge by holding the pile in place. The device can be activated by either push button or by integrating the function into the cutting program.

Fitted into the clamp, the knife is cleaned on the backside during every single cut. Includes a non-stick knife and is the perfect option for cutting glued products.

KNIFE CHANGE

EASY - SAFE - FAST